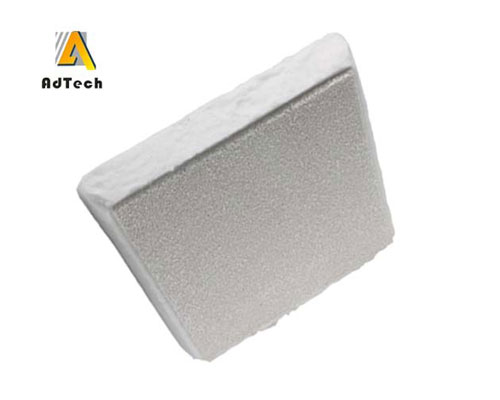

Zirconia ceramic filter widely used in iron and steel industry. The function of die casting industry has increased proportionally and brought about many changes. These changes have resulted in high quality products, especially metal castings, which can be used in many manufacturing plants. Although filters help purify compounds in molten form, zirconia ceramic filters for steel are added to castings of various shapes.

Zirconia Ceramic Filter

Ceramic foam filter has the advantage of providing the purification form of castings.

Most of the die casting industries use ceramic foam filters to remove impurities in molten metals or alloys. Due to this filtration process, the casting is designed to be strong and robust. Most industries use this filter to obtain high standard products that can be used in different manufacturing units. In addition, the demand for refined and high-quality products may be greater than for porous and rough items. The use of ceramic filters is becoming more and more popular in these industries due to the presence of many impurities in molten metals and the higher requirements for high-quality products.

Since casting products from the mold manufacturing industry can be used for a variety of other equipment, they must have different shapes. Ceramic filters for steel help to solve this problem, which helps to give castings different shapes. Ceramic foam filter also has a good purification system. As a result, many industries have replaced the filters and produced more demanding products, allowing higher quality products to be used in other industries.