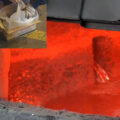

Aluminum ash refers to the scum generated on the surface of the melt in the process of electrolytic aluminum liquid transfer, purification, impurity removal, alloying, casting, and salt slag and aluminum recovery process. The treatment of aluminum ash is an important process for environmental protection in the aluminum industry.

Treatment of Aluminum Ash

Handling Qualification Issues

In the short term, the overall hazardous waste treatment capacity of aluminum ash is insufficient, and some hazardous waste may need to be stored. If aluminum ash is in danger, the number and capacity of enterprises with aluminum ash processing qualification will be insufficient in the short term, and it will take time to add new capacity. Then there is currently only one way to produce aluminum ash, which is to establish a dedicated warehouse for storage. The problem is that, first, do enterprises have the space to expand factories, and large enterprises can still have this condition. How about SMEs? Whether there will be a warehouse dedicated to the centralized storage of aluminum ash for small businesses. The second is that even with such a warehouse, security and risk issues will also increase costs.

Transportation Problem

In some areas, enterprises with qualifications to deal with hazardous wastes have insufficient production capacity, and there is a risk of premium for short-term treatment costs. Since the transportation of hazardous waste across the land requires the permission of the local environmental protection department. In general, it is difficult for some regions to be willing to accept hazardous waste, so it is relatively difficult to handle hazardous waste across provinces. However, the local qualified production capacity for hazardous waste treatment is likely to be insufficient, resulting in the uplift of treatment costs.

Technical Problem

The current technology for processing aluminum ash is not mature. Similar to red mud, there is currently no general method for batch processing of aluminum ash. Even if the follow-up occurs, there is also a vacuum period for research and development, which will exacerbate short-term processing capacity shortage problems.

Current Situation

At present, most of the aluminum ash processing methods are refined aluminum to produce compound ingots. That is to say, the current method for enterprises to deal with aluminum ash is outsourcing. Once the enterprises in danger need to spend extra costs to deal with, the cost of the one-time return increases more than a little. Taking the current aluminum ash selling price of about 1,000 yuan/ton, taking the recycled aluminum industry as an example, each ton of recycled aluminum smelting will produce about 3%-10% of aluminum ash. Based on the average 6.5% aluminum ash production, if the processing cost per ton of aluminum ash reaches 4,000 yuan/ton, the cost of recycled aluminum per ton will increase by 325 yuan/ton. AdTech offers degassing units, CFF filtering system, refining flux for refining aluminum ash.