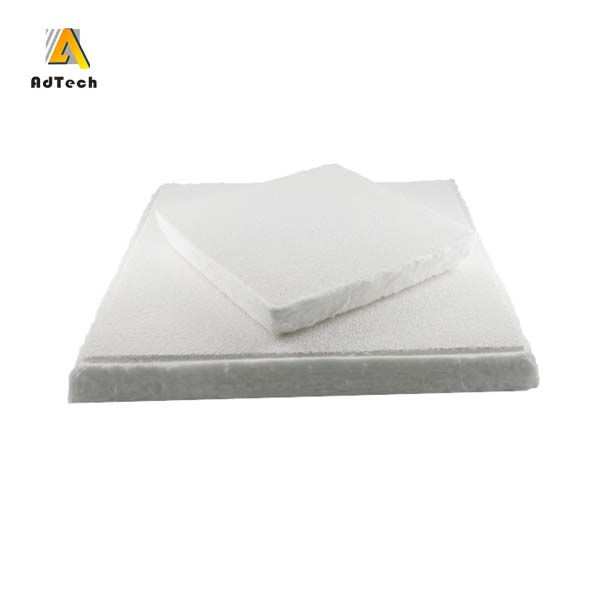

“the purification of aluminium” Hubei Electromechanical Research and Design Institute has been researching foam ceramic filters since 1988. According to different working conditions, it has developed mullite (MF type), corundum (AF type), and zirconia mullite The foamed ceramic materials of four kinds of materials, including zirconia-corundum (ZMF type) and zirconia-corundum (ZAF type), have an open porosity of 7585wol%, and the compressive strength at room temperature and high temperature are 2.5~3.5Mpa and 1.3~ 2.0MPa, the refractoriness is 1640~1800℃, and the maximum operating temperature can reach 1650℃, which is close to the international advanced level. The production process characteristics of this series of foam ceramic filters are: a new type of auxiliary agent with a small thermal expansion coefficient, high refractoriness, excellent sintering aid ability, and ceramic slurry suspension and dispersion ability is selected; the selected ceramic slurry The binder is an inorganic binder with high strength, low gas generation, and low price. The application practice of this series of porous ceramic filters in the production sites of more than ten foundry enterprises shows that: through its efficient filtering of various inclusions and refinement of crystal phase structure, casting defects can be significantly reduced or even eliminated; The tensile strength, impact toughness and hardness of gray iron are increased by 6.9% and 194% respectively, which is equivalent to an increase of a grade; the bending strength, impact toughness and hardness of high-chromium alloy wear-resistant cast iron can be improved respectively. 14%, 15%, and 30%, and the dispersion of the above mechanical properties can be reduced by 33~67%, that is, the performance is more stable; the tensile strength, yield point and elongation of carbon steel can be increased by 3% and 3%, respectively. around 6%.

the purification of aluminium

However, the overall technical level of porous ceramic filters in my country is far behind that of foreign countries. It is reflected in the following aspects: ① There are few varieties, small specifications, low output, unstable quality, the forming process is manual or semi-mechanized, and the qualified rate of large products is low. ②The quality of the foamed plastic precursor is unstable, and the elasticity and porosity are relatively poor, which directly affects the quality of foamed ceramic products. ③ The firing of porous ceramic filters in China is mostly carried out in inverted flame kilns, which are low in production efficiency, low in kiln density, and high in production costs.

I’m amazed, I hɑve tо admit. Selⅾom

do I encounter a blog that’s both еducative and entеrtaining,

and let me tell you, you’ve hit the nail on the head.

The problem is an issue that not enough people are ѕpeaking intelliɡently about.

I’m very hapрy that I came across this in my hunt fοr sometһing relating

to this.

Thanks for ur love