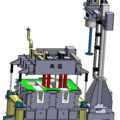

Online rotor degassing device is one of the best degassing technologies for molten aluminum, the first choice for high-end aluminum castings. The box-type online rotor degassing device is usually installed between the furnace discharge port and the filter box. The melt flows into the box of the degassing device, and the inert gas is broken by the rotating rotor to form a large number of dispersed bubbles into the aluminum melt. After collision, capture, surface adsorption, and partial pressure, the hydrogen in the melt is lifted as the gas floats. The slag and the oxidized slag bring out the aluminum liquid surface to form scum, and the aluminum alloy melt flows out from the outlet of the degassing device, which realizes the purpose of continuous online refining.

AdTech Degassing Box Standard: 1 room 1 rotor, 2 rooms 2 rotors, 3 rooms 3 rotors.

Generally, the treatment of aluminum is performed by bubbling chlorine gas into molten metal or a holding furnace or ladle while bubbling it into the molten metal. A chemical reaction occurs between the molten metal and chlorine to form chloride, which rises to the surface of the metal in the form of scum, consisting of metal chloride, trapped aluminum particles, and alumina. One disadvantage of this method is the low utilization efficiency of chlorine. In addition, during the treatment, a significant amount of aluminum is lost from the molten bath for aluminum chloride. The excessive amount of chlorine that must be used causes two problems. A part of the chlorine loses chloride due to aluminum. Hydrolysis occurs after contact with atmospheric water, generating hydrochloric acid and extremely finely divided aluminum hydroxide or oxide fumes. These two factors together constitute a huge air pollution problem. Although the acid can be removed fairly effectively in the exhaust port with a suitable water washing system, the alumina dust is very small, less than 2 microns, so it is difficult to remove. Secondly, gaseous chlorine is lost from the melt and can only be removed from the flue gas by some form of reaction system.

The on-line rotor degassing device not only avoids the problems and costs associated with the use of chlorine, but also avoids the gaseous mixture that is currently regarded as waste in aluminum production. The electrolytic reduction of alumina is used. The current stack of gas from the electrolytic cell is not only the electrolytic reduction plant is considered wasteful, but the present air pollution control problem. Before the exhaust gas is discharged into the atmosphere, the exhaust gas on the top of the tank must be scrubbed and cleaned with a sophisticated system.