The rotating degassing equipment for aluminum alloy refining can remove hydrogen and slag, purify aluminum liquid, and eliminate pinholes in castings. The online rotating degassing device adopts the refining process of rotating degassing and has a long service life. The degassing rotor, heater protection sleeve, and thermocouple protection sleeve are all made of ceramic manufacturing technology, which can meet the requirements of producing high-precision aluminum.

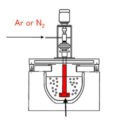

The working principle of rotating degassing equipment is that when the motor drives the rotor to rotate, the argon gas will break into small bubbles. The presence of these small bubbles reduces the hydrogen concentration in the aluminum liquid and the partial pressure on the surface, thereby reducing the hydrogen concentration in the aluminum liquid. The hydrogen is taken out from the surface of the aluminum liquid by argon gas, burned on the liquid surface and consumed.

When the small bubbles of argon move to the liquid surface at the bottom of the aluminum liquid, the hydrogen dissolved in the aluminum liquid hits the argon-aluminum liquid interface, and the hydrogen changes from the dissolved state to the adsorbed state. The gas atoms in the adsorption layer react to form hydrogen molecules. As the bubbles grow, they rise to the surface of the molten aluminum and burn off.

When the small argon gas bubbles move from the bottom of the molten aluminum to the surface, they agitate the particles of inclusions suspended in the molten aluminum, and the inclusions collide with each other, gather and grow up. When the inclusions reach a certain size, they may collide with floating bubbles and be caught. Then bring it to the surface of the liquid to achieve the effect of slag removal.

There are two models of bubble trapping inclusions, which produce inertial collision trapping for larger inclusions. For smaller inclusions, it is difficult to collide with the bubble, but tangential trapping may occur around the bubble.

Because argon is an inert gas, and molten aluminum does not react. It can replace the hydrogen in the aluminum melt, thereby greatly reducing the hydrogen content in the aluminum melt and improving the mechanical properties of the aluminum alloy.

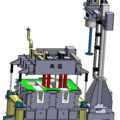

The online degassing device should be installed between the furnace and the casting equipment. It is used to remove hydrogen and slag from molten aluminum. The online degassing device has dual functions: processing and heating. It serves the high-precision molten aluminum purification industry.