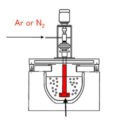

After melting and refining of casting aluminum alloy, in the process of subcontracting and degassing, aluminum water is taken out from the subcontract, time before and after adding aluminum flux, nitrogen flow of rotating degassing aluminium and converter speed are rotated. Degassing time, diameter and height of graphite rotor. The density of molten aluminum is measured and analyzed in the production process.

After aluminum flux degassing, the degassing effect of aluminum liquid in different positions is not consistent, and the position near the turntable is the worst.

The flow rate of nitrogen has a certain influence on the location of bubbles. The larger bubbles spread farther, but it will cause a large amount of aluminum liquid throwing, which will harm the production safety.

The rotating speed has a great influence on the degassing effect of molten aluminum. High speed ensures more gas diffusion and ensures that molten aluminum does not roll.

The effect of refining agent input time on the rotating degassed aluminum is very small, which can not achieve the purpose of refining molten aluminum. It can treat scum on the surface of molten aluminum. It is recommended to use slag remover to treat aluminum slag on the surface. According to the specification of refining agent, the service temperature of refining agent is 700-750 ℃, and the service temperature of deslagging and degassing agent is not less than 680 ℃. It’s not easy to control.

The rotational speed and nitrogen flow rate must be used simultaneously to ensure degassing effect and molten aluminum will not roll and be oxidized. The flow rate of 15R / min can meet the requirements at 400R / min.

In the rotating degassing aluminium process, the rolling and splashing of molten aluminum will affect the degassing and oxidation of molten aluminum. After degassing, the aluminum slag and sample density on the surface of aluminum melt can reflect the degassing effect of aluminum melt.