The aluminum liquid rotary degasser is an online device for aluminum and aluminum alloy melts in the casting process, and its function is to greatly reduce the hydrogen content in the aluminum liquid and improve the quality of aluminum and aluminum alloy products. During the degassing process of the degassing box, the oxygen content in the furnace chamber will often increase due to the escape of outside air, and the moisture will also increase, and the temperature of the furnace chamber will also be reduced at the same time. These factors will reduce the effect of hydrogen removal. , affecting the quality of the product.

In addition, the existing aluminum liquid rotary degasser inlet and outlet are at the same height, and the process of degassing and slag removal of aluminum liquid is carried out in the cavity, and there is also a large amount of aluminum liquid in the cavity after use, and these aluminum liquids only The cavity can be discharged through the slag discharge port of the degassing box and become waste aluminum, which greatly reduces the yield of aluminum in the production process. And after the cavity is used, solidified aluminum blocks and aluminum slag are easy to deposit in the box, which is not easy to remove. After the liquid aluminum degassing box is used once, the residual aluminum liquid is about 1-2 tons, which is especially unbearable for small furnaces and aluminum liquid casting experimental lines.

Utility model content

For the problems existing in the prior art, the utility model provides a kind of aluminum liquid degassing box and aluminum liquid rotary degasser, to solve the existing aluminum liquid degassing box easy escape into air, deposition aluminum liquid, aluminum Lumps and slag and technical problems that are not easy to clean.

Solution of the present utility model is achieved in that:

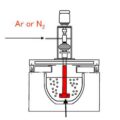

The utility model provides a kind of aluminum liquid degassing box, comprises box body, case lid; Box body comprises box wall and is arranged on the hollow cavity body in the box wall, and the cavity body opening upwards; Cavity body comprises bottom wall and inner wall ; On the upper part of the inner wall of one side of the cavity, there is a liquid inlet connected to the outlet of the launder; on the bottom of the inner wall on the other side of the cavity, a liquid outlet connected to other equipment is provided; on the inner wall at one end of the liquid inlet of the cavity Install an underflow plate to separate the cavity from the outside world

rotary degasser