Although there are many process methods for the refining of aluminum alloy melt, they still cannot meet the production needs of the aluminum industry, especially the production of military aluminum alloys such as aerospace. At present, refining and purification in the production process of cast aluminum alloy is still a basic problem, it has not been completely solved for a long time. A large number of waste products are generated in the factory, and many high-quality aluminum alloy castings cannot be produced.

Refining of Aluminum Alloy

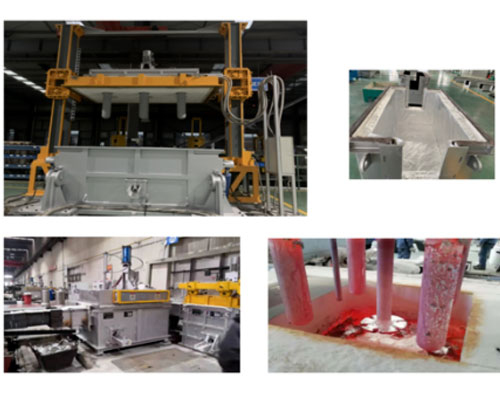

Due to the shortcomings of low efficiency, poor purification effect, high labor intensity and environmental pollution, traditional furnace treatment methods have been gradually replaced by continuous purification outside the furnace. It is a common development trend for domestic and foreign aluminum processing enterprises to use continuous purification treatment outside the furnace to replace the gap purification treatment inside the furnace.

It is very difficult for a single refining method to efficiently degas and remove inclusions at the same time. The degassing effect of vacuum treatment is good, but the degassing effect is not ideal. The filtering method has a significant effect in removing inclusions, but the degassing effect is poor. If you want to have both benefits at the same time, it is best to use compound refining technology. Therefore, composite refining treatment has become the main development direction to obtain high-quality molten aluminum.

The continuous purification outside the furnace has also been developed from a single function to a multi-function. The combined purification technology is used to combine degassing purification and filtration and impurity removal, that is, while the gas flux is used for hydrogen removal and purification, it has a better effect on removing inclusions. The strong purification process can achieve multiple continuous purification of the melt in the same device, thereby greatly improving the purification effect.