The process and operation of removing gases, inclusions, and harmful elements from the melt to obtain good aluminum liquid is called refining. It is also called purification. There are many refining methods for aluminum alloys, which can be divided into two basic types: adsorption refining and non-adsorption refining. According to the refining position, it can be divided into three types: furnace refining, online refining, and ladle refining.

Refining Methods for Aluminum Alloys

Refining Methods for Aluminum Alloys

Adsorption Refining

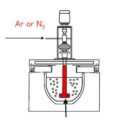

Adsorption refining refers to the physical and chemical reaction between the aluminum melt and the adsorbent (such as various gas, liquid and solid refining agents and filter media) directly, so that the adsorbent and the gas and solid non-metallic inclusions in the melt Physical or mechanical action to achieve degassing and slag removal. Adsorption refining only works on part of the melt that the adsorbent reaches. The degree of melt purification depends on the contact conditions, that is, the contact area between the melt and the adsorbent, the duration of contact, and the surface state of the contact. It belongs to adsorption refining: air blowing refining, chloride salt refining, flux refining, melt filtration, etc.

The purification mechanism of adsorption refining is mainly to use the law of partial pressure of gas to remove gas, and to use the compound formed with hydrogen to remove gas; in terms of slag removal, it mainly includes adsorption slag removal, dissolution slag removal, compound slag removal, and filtration slag removal. When the active refining agent is used, it also has the function of removing sodium, calcium, magnesium, lithium and other metal impurities (metal impurities that are more active than aluminum) in the melt. Adsorption refining is currently the most widely used refining method in the aluminum industry.

Non-adsorption Refining

Non-adsorption refining refers to changing the equilibrium state of the metal-gas system or the metal-inclusion system without relying on the addition of adsorbents in the melt, so that the gas and solid non-metallic inclusions are removed from the aluminum melt. Method of separation. Non-adsorption refining has a refining effect on all aluminum melts, and its refining effect depends on the external conditions that break the balance and the movement characteristics of the aluminum melt, inclusions, and gases.

Non-adsorption refining includes: standing treatment, vacuum treatment, ultrasonic treatment, pre-solidification treatment, etc. The purification mechanism of non-adsorption refining mainly uses the influence of temperature and pressure on the solubility of gas in aluminum and the phenomenon of “cavitation” in the melt caused by high-frequency mechanical oscillation; in terms of slag removal, it mainly uses the difference in specific gravity And auxiliary flotation function during degassing. Except for standing treatment, other non-adsorption refining methods are rarely used in the actual production of general aluminum factories.