According to its development process and characteristics, the production methods of refining agent processing are divided into fusion method, drying mixing method and comprehensive mixing method.

Fusion Method

The fusion method is to perform high-temperature dehydration and high-temperature melting treatments with high melting point (for aluminum alloy) inorganic salts according to the low eutectic point ratio to produce low melting point mixed salt, which is then crushed into blocks or powdered after condensation. This method dehydrates thoroughly.

When using the fusion method to make refining agents, you can first melt the low-melting chlorine salt, add refractory ingredients at a certain temperature, fuse together at high temperature, and then cast into blocks, store in a dry container, and break before use , Milled and sieved. The refining agents made by the melting method is of high quality, can fully remove the water, and has a uniform composition. Generally, the refining agents is made by this method.

The production process can be divided into two stages: melting of the refining agents-hot processing of the refining agent, crushing of the refining agents and grinding-cold processing of the refining agent.

Refining Agent Thermal Processing

First of all, the ingredients should be rationally prepared according to various ingredients, and the furnace charge should be clean and free of visible mechanical impurities and dirt. The chemical composition of each material should meet the relevant standards for use. Then, the smelting of the refining agent is performed.

At high temperatures, potassium chloride is easily volatile and lost, and cryolite decomposes to generate AlF3 gas and run away. In order to ensure the composition and content of the refining agents and give full play to the impurity removal effect, the melting temperature should not be too high and the time should not be too long. After smelting, select representative samples for chemical analysis.

Refining Agent Cold Processing

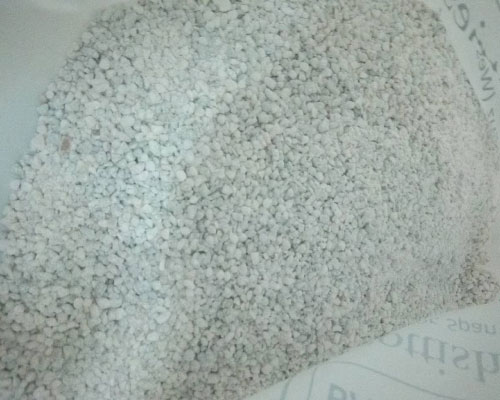

The melted refining agents should be placed in a dry place or in a sealed subway box. When required for production, it will be crushed and milled manually or mechanically, and processed into a block or powder refining agent with a certain particle size as required.

The refining agent is first crushed into large pieces, and then sent to the crusher to be crushed to an appropriate particle size. The crushed blocks are screened manually or by steel screens.

Lump or powder refining agent is placed in the atmosphere, it is easy to absorb water and become humid. Using it in aluminum alloy production will increase the gas content of the aluminum alloy melt and directly affect the product quality. Therefore, the finished refining agents should be placed in a dry room and taken out during temporary use.

When processing the refining agent, it should be released and used in the order of production. Due to too long time or improper storage, etc., the water content must be sampled and analyzed in advance, generally not more than 2%, otherwise it needs to be dried or remelted again.