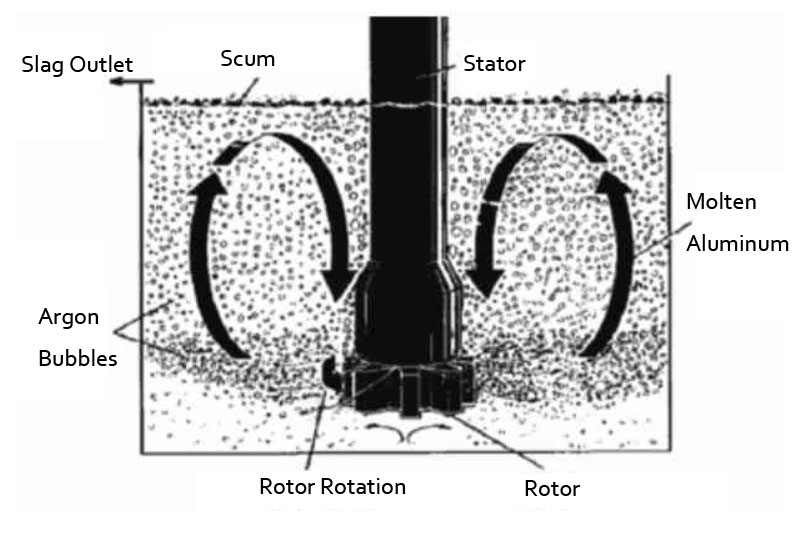

The purification technology of liquid aluminum, which is based on hydrogen removal, mainly includes bubble floatation, vacuum treatment, ultrasonic treatment, and rare earth hydrogen storage. Because of its simplicity and high efficiency, the bubble floatation method is still a widely used aluminum liquid hydrogen removal purification technology. AdTech online degassing unit adopts bubble floatation method for aluminum degassing.

The basic principle of the bubble floatation method has been agreed by the industry, that is, a large number of external hydrogen-free bubbles are created in the molten aluminum, that is, the initial partial pressure of hydrogen in the bubbles is zero. Therefore, the hydrogen dissolved in the aluminum liquid continues to enter the bubble, so that the partial pressure of hydrogen is established in the bubble, and it continues to increase, until the hydrogen partial pressure in the bubble and the hydrogen concentration in the aluminum liquid meet the kinetic conditions for hydrogen removal. balance. At the same time, the bubbles float up in the molten aluminum and finally escape the liquid surface to achieve the purpose of hydrogen removal. The bubbles also have the function of adsorbing oxidized inclusions in the molten aluminum, so the part of hydrogen adsorbed on the inclusions is also removed.

The bubble floatation method is a traditional hydrogen removal technology, but it has been greatly developed today. According to the types of refining agents that cause hydrogen removal bubbles in molten aluminum, they can be roughly divided into solid purification agents and gas purification agents. The former mainly refers to the purifying agent represented by chloride salt or chloride, and the latter mainly refers to the purifying agent represented by Ar and N2. Although the former is still widely used at present, it is impossible to have a broad application prospect facing the new century due to recognized serious pollution and other reasons. Although various pollution-free refining agents have come out since 1979, they have caused controversy, and the pollution of molten aluminum and environmental issues continue to be concerned. This kind of purifying agent is usually based on some kind of salt. At present, there is no prospect of completely replacing chlorine salt or chloride and making solid purifying agent widely used.

In contrast, the purification technology using gas purifiers has developed rapidly in recent years. Because it can improve the hydrogen removal efficiency of molten aluminum by improving the hydrogen removal kinetic conditions and other means, and it can achieve convenient operation and no pollution, it will definitely attract people’s attention. Its effects and advantages are gradually recognized by the peers, and its technology itself has been continuously improved.

In order to pursue high-efficiency, low-consumption, and pollution-free aluminum liquid purification technology, people will seek new progress in the following aspects under the general trend of bubble floatation purification technology using gas solvents as purification agents.

Improve the blowing method of the gas purifier and select the best kinetic conditions for the removal of hydrogen from the molten aluminum. Under certain conditions in the molten aluminum smelting process, the thermodynamic conditions for the removal of hydrogen from the molten aluminum are usually determined, in order to pursue the best hydrogen removal efficiency , We must start with improving its dynamic conditions.

- Improve the blowing method of gas purifier and choose the best kinetic conditions for removing hydrogen from molten aluminum.

- Use pure inert gas flux.

- Improve the purity of gas purifiers.

- Use composite gas as purifying agent.

- Adopt joint purification technology.