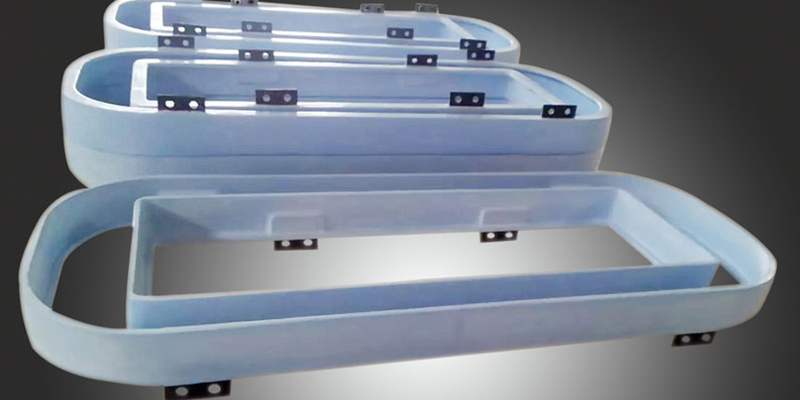

Skim Ring is used in conjunction with the crystallizer. By setting Skim Ring, the filtered aluminum liquid enters the range of the ring formed by Skim Ring.

Skim Ring can block slag such as oxidized slag and prevent slag such as oxidized slag from entering the crystallizer, thereby reducing the risk of ingot contamination by slag.

Specification

| items | Dimensions | Special dimensions | Package | Special package |

| Flow pipe | 100-2600mm | As drawing | 10pieces/box | As required |

Product Advantages

Scour resistance, no flaking, smooth surface, no pollution to aluminum liquid.

Isolate oxide slag, stable and safe casting.

The metal retaining ring of the slag retaining ring can be cast by hanging on the crystallizer.

Instructions for Use

1. Skim Ring adopts the structure of the inner and outer jackets. When the fixed structure is released, the slag block can be freely installed in the annular installation cavity between the inner ring plate and the outer ring plate.

2. After the fixing structure is tightened, the inner ring plate and the outer ring plate are fixed to clamp the slag block, and together form an integral slag ring.

3. Corresponding to the structure of the crystallizer, install a slag retaining ring with a metal retaining ring for matching casting.

4. According to the amount of metal liquid and the size of the crystallizer, the test buoyancy is too large. The existing slag retaining ring metal ring buckle can be added with a weight metal sheet to meet the needs of stable casting.

5. The end of regulation and control, so that accurate assembly and use, you can start casting.