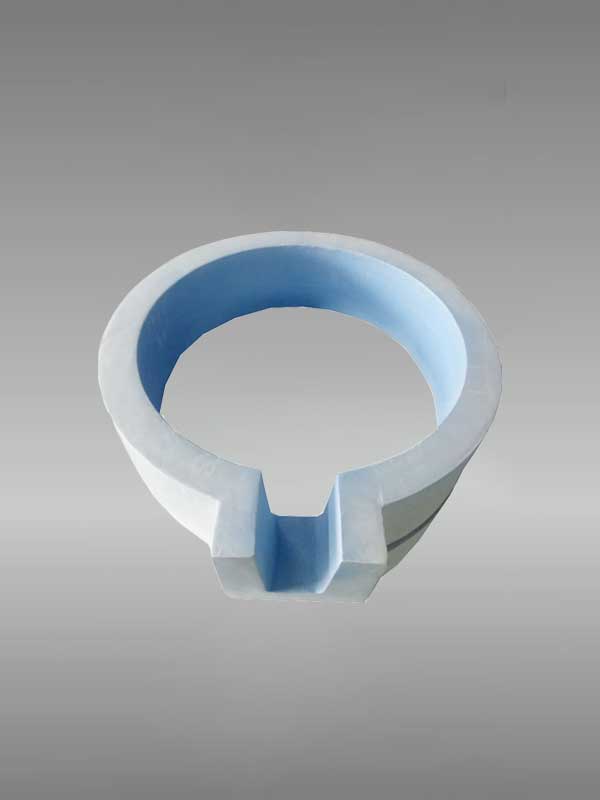

Pouring Cup is an important part used in the casting process of aluminum and aluminum alloy rods. Its main function is to make aluminum melt flow slowly and smoothly through the crystallizer, and then cool and crystallize into aluminum rod products.

If there is no drainage of the Pouring Cup, the aluminum melt will be unstable, which will not help it form a reasonable temperature field in the crystallizer.

Specification

| 3in | 3.5in | 4.5in | 5in | 5.5in | 6in | 6.5in | 7in |

| 8in | 9in | 10in | 12in | 14in | 16in | 18in | 20in |

Technical Parameter

| Item | Denisity (g/cm3) |

Compression Strength (Mpa) |

Thermal Expansivity (X*10-6/℃) |

Max Working Temperature (℃) |

| Index | 1.4-1.5 | 15-16 | 4-4.5 | >1000 |

The melting and casting of aluminum rods include melting, purification, impurity removal, degassing, slag removal, and casting processes.

1. Ingredients: According to the specific alloy grade to be produced, calculate the amount of various alloy components added, and reasonably match various raw materials.

2. Smelting: The prepared raw materials are added to the melting furnace for melting according to the process requirements, and the impurities and gas in the melt are effectively removed by means of degassing and slag refining.

3. Casting: Under certain casting process conditions, the melted aluminum liquid is cooled and cast into round casting rods of various specifications through a deep well casting system.

Aluminum rods: Aluminum is a light metal, and its compounds are widely distributed in nature. The aluminum resource in the earth’s crust is about 40-50 billion tons, second only to oxygen and silicon, and has the third place. Among the metal varieties, it is the second-largest metal after steel. Aluminum has special chemical and physical properties. It is not only light in weight and firm in texture, but also has good ductility, electrical conductivity, thermal conductivity, heat resistance, and nuclear radiation resistance. It is an important basic raw material for the development of the national economy.

Aluminum is an extremely rich metal element on the earth, and its reserves rank second in the metal. It was not until the end of the 19th century that aluminum emerged as a competitive metal in engineering applications and became popular. The development of the three major industries of aviation, construction, and automobiles requires that the material properties have the unique properties of aluminum and its alloys, which greatly benefits the production and application of this new metal, aluminum.

One-Stop Shopping for Aluminium Melting Materials