Brief description: The liner with a relatively large flow rate of equipment (deep bed filter, degassing unit, and Tube filter box) has a relatively sizeable residual amount of molten aluminum. During the discharge process, the molten aluminum at the discharge port overflows due to the pressure difference:

1. The distance between the substrate and the top of the launder of the original discharge device is too small, and the aluminum liquid is easy to overflow;

a. The compression device of the original discharge device is too laborious and the handwheel’s position is too low to operate.

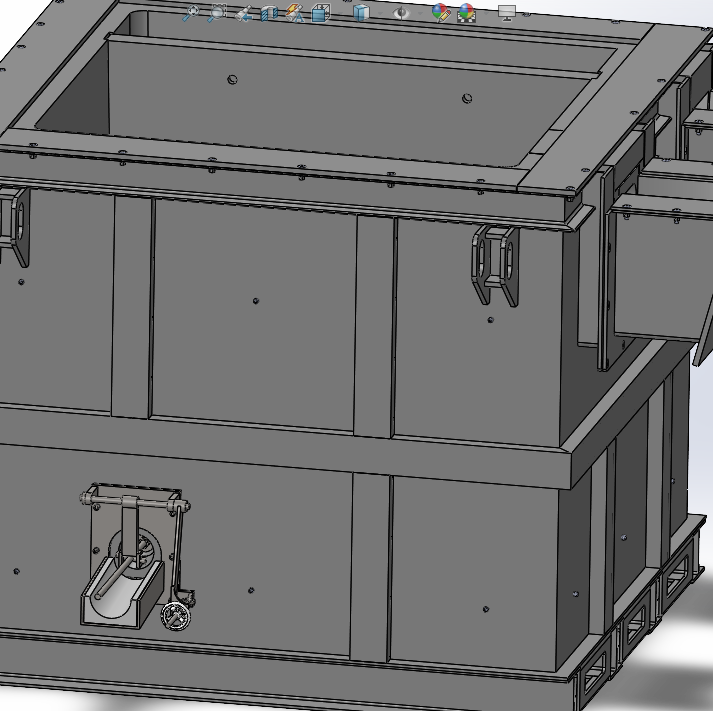

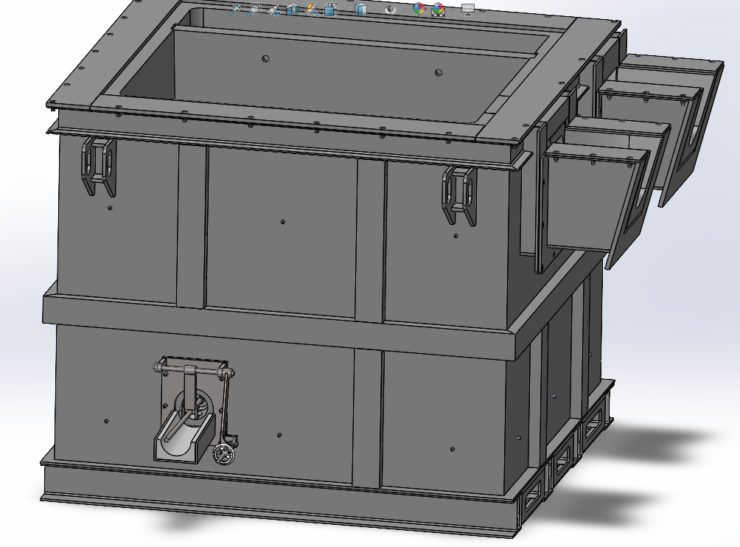

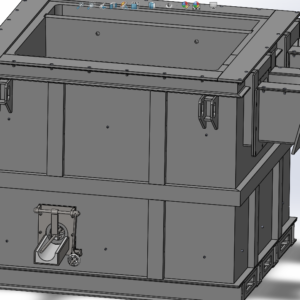

discharge device

b. Improvement method: According to the questions and references raised by customers.

The radius and height of the inner arc of the lining are increased to ensure that the aluminum liquid will not overflow from the discharge launder due to the sizeable residual amount of aluminum liquid during the discharge process.

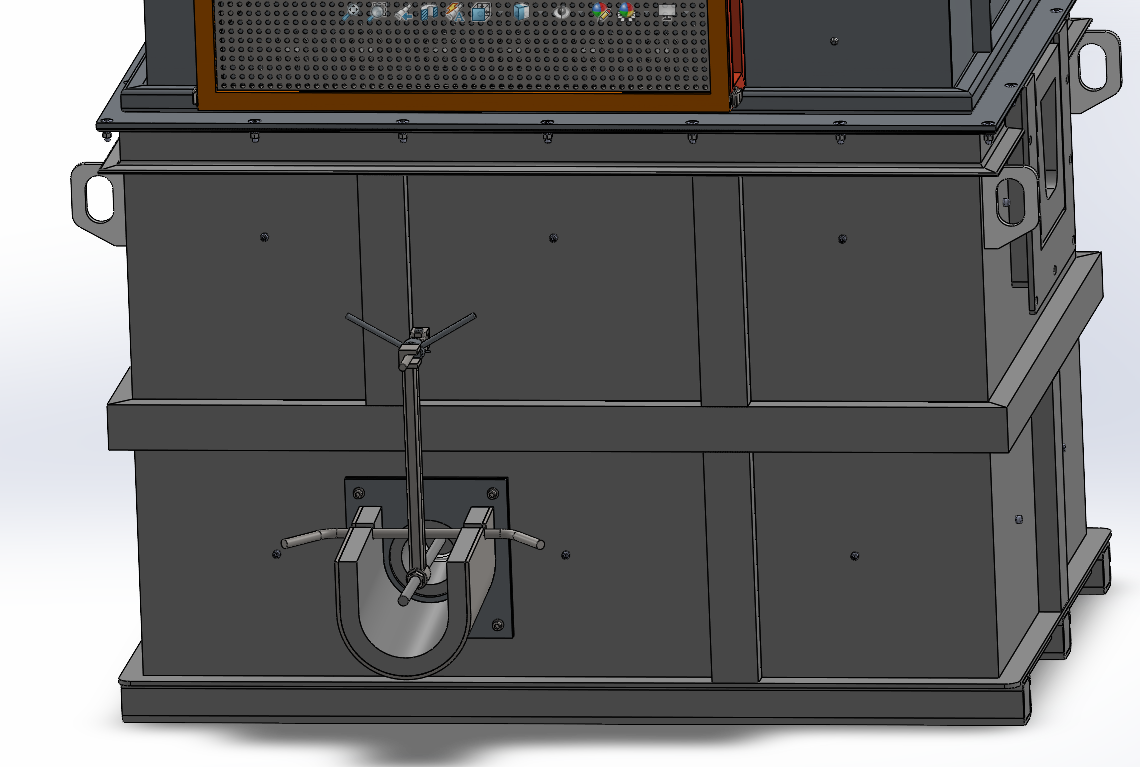

1. Change the compression method of the plug. The current design method has a compression height of 860mm, the force arm of the compression device is large, and the operation is easy and convenient without squatting or bending over.

2. The pressing wheel is made like the ship rudder, which is easy to operate and it is convenient to add an extension rod when more force is required.

3. On-site application

discharge device

This improvement method has been applied to Ruyuan East Sunshine Equipment, and after the factory test, it is indeed labor-saving compared with the original compacting device.