Ceramic Foam Filter product specifications are 7 * 7in, 9 * 9in, 12 * 12in, 15 * 15in, 17 * 17in, 20 * 20in, 23 * 23in, 25 * 25in, 26 * 26in or customized according to the shape and size of customer needs.

The mesh number is 25, 30, 35, 40, 45, 50, 55, 60, 70, 80, and 90 PPI.

It has the advantages of high strength, erosion resistance, strong adsorption capacity, and effective removal of tiny inclusions in aluminum liquid.

A ceramic Foam Filter is used in conjunction with CFF Filter Box.

Ceramic Foam Filter composition and assembly

Ceramic Foam Filter

Expansion seal

CFF filter box

ceramic foam filter

Ceramic Foam Filter Production Process

1. Adopt organic foam with a three-dimensional network structure and connected pores as a carrier, and invade it into the thixotropic alumina material slurry.

2. Use automatic extrusion equipment to evenly distribute the slurry in the foam skeleton.

3. Drying, curing, high temperature 1180 ℃ roasting for tens of hours.

Installed in the filter box for aluminum alloy liquid impurity filtration, to meet the production of high value-added, high-tech performance aviation, transportation, and other aluminum alloy precision casting.

Such as computer hard disks, printing PS board bases, can-making materials, jet turbine engine fan blades, and other products.

Product Advantages

1. Can effectively remove large inclusions in the aluminum liquid, and effectively adsorb small inclusions of small size.

2. No slag, and no pollution to the aluminum liquid.

3. Good thermal shock resistance.

4. Automated assembly line production, three calibration procedures, and high accuracy of product dimensions.

5. Improve the surface quality of aluminum ingots, aluminum rods, and aluminum coils, improve product performance, and improve the microstructure.

foam ceramic filter

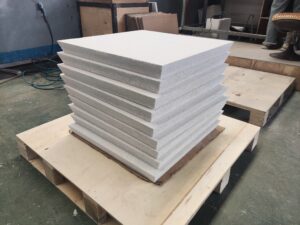

Standard sizes for Ceramic Foam Filter

Dimension (± 3 mm

): 7x7in 9x9in 12x12in 15x15in 17x17in 20x20in 23x23in 26x26in

Thickness: 50 ± 2 mm

Bevel Angle: 17.5± 1.5°

Special Dimension: square, rectangular, round, trapezoidal, abnormal, or customized as per the requirement.

Technical Parameters:

| Item | Density (g/cm³) |

Rupture Modulus (816℃ /Mpa) |

Comprehensive Strength (Mpa) |

Operating Temperature (℃) |

Sealing gasket expanding temperature (℃) |

| Index | 0.45 | 5.5 | 0.8-1.0 | 1350 | 450-550 |

Pore size for Ceramic Foam Filter:

Pores amount in any 25.4mm length filter

| Mesh Number(PPI) | 10 | 20 | 30 | 40 | 50 | 60 |

|---|---|---|---|---|---|---|

| Pore Density(PCS) | 8-12 | 18-22 | 28-32 | 38-42 | 48-52 | 58-62 |

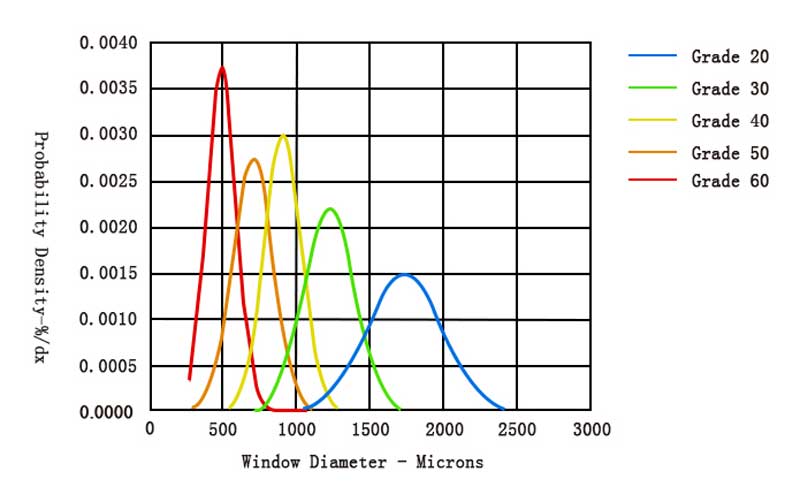

The distribution curve of pore size

Window size distribution of ceramic filter

Window size distribution of ceramic filter

Filtration efficiency

| Pore Size(PPI) | 20 | 30 | 40 | 50 | 60 |

|---|---|---|---|---|---|

| Inclusions Diameter(um) | 80 | 40 | 20 | 10 | 5 |

| Filtration Rate(%) | 78 | 85 | 88 | 92 | 95 |

Flow Selection

| Specifications (mm) | Effective filtration area(%) | Filtration flow range(kg/min) |

|---|---|---|

| 7in(178*178*50) | 75 | 22-56 |

| 9in(229*229*50) | 75 | 25-80 |

| 12in(305*305*50) | 80 | 50-156 |

| 15in(381*381*50) | 85 | 85-252 |

| 17in(432*432*50) | 86 | 110-335 |

| 20in(508*508*50) | 88 | 160-478 |

| 23in(584*584*50) | 89 | 210-640 |

| 26in(660*660*50) | 90 | 276-830 |

Instructions for use

1. Keep the Cff filter box clean and free of damage.

2. Put the filter plate into the CFF filter box and press the sealing gasket tightly.

3. Preheat the filter box and filter plate evenly so as to be close to the temperature of the molten aluminum. The preheat temperature of the filter plate is not less than 260 ℃. Preheating can use electric or gas heating, or normal heating for 15-30 minutes.

3. Observe the changes in the aluminum hydraulic head during casting to maintain the normal demand of aluminum liquid flow control.

4. During the normal filtration process, the launder is filled with aluminum water to avoid the disturbance of too large or too small aluminum liquid.

5. After filtering, remove the CFF and clean the filter box.

aluminum die-casting ceramic foam filter

Packing and Delivery