Online degassing systems directly affect the quality of aluminum castings. In order to minimize the hydrogen in the molten aluminum, it is necessary to provide a method for degassing the molten aluminium, which can better remove the hydrogen in the molten aluminum.

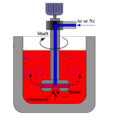

In view of the above problems, AdTech offers online aluminum degassing systems that can degas more efficiently and improve product quality. Inert gas is introduced into the molten aluminum in the ladle and put into the rotor, and the rotor is rotated in the molten aluminum at a speed of 400~500r/min. Metal degassing systems remove hydrogen and inclusions from molten aluminium.

Degassing systems are designed for on-line degassing of molten aluminium with high flow rates, high gas content and high inclusions. It has two independently controllable steering rotors that rotate in opposite directions to provide more powerful stirring. The air volume is large, the equipment is directly placed on the launder, the horizontal crane can be hoisted or the wear parts can be replaced, and the good thermal insulation design can provide 24-hour online uninterrupted degassing.

The principle of the aluminum online degassing system is the solubility of hydrogen in aluminum and the partial pressure of hydrogen in the aluminum melt. When the hydrogen partial pressure corresponding to the hydrogen content in the aluminum melt is greater than the hydrogen partial pressure in the actual gas in contact with the aluminum melt, the hydrogen in the aluminum melt will diffuse into the gas phase to achieve hydrogen removal.

Therefore, in order to remove as much hydrogen as possible from the aluminum melt with as little inert gas as possible, the following principles should be followed for online inert gas hydrogen removal:

The lower the content of hydrogen and oxygen in the inert gas, the better.

The more bubbles formed by blowing an inert gas into the melt, the smaller the bubbles and the better the dispersibility.

The longer the bubbles stay in the aluminum melt, the better.