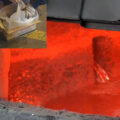

The slag mixed into the ingot or other non-metallic inclusions falling into the ingot are called non-metallic inclusions, commonly known as slag inclusions.

The macroscopic structure is characterized by no fixed shape, black pits, and no clear boundary with the matrix. The characteristics of non-metallic inclusions can only be clearly revealed after the low-magnification test piece of the ingot is diffusely eroded by the alkaline aqueous solution.

The fracture structure is characterized by black strips, blocks or flakes, which is very different from the matrix color and is easy to distinguish. The microstructure features are mostly flocculent black disordered tissues, which are composed of black lines and have obvious color difference from the white matrix.

Non-metallic Inclusions Formation mechanism

Non-metallic inclusions are usually flux, slag, furnace lining, oily dirt, mud and larger block oxides, nitrides, carbides, sulfides that fall into the ingot along with the liquid metal during the casting process, and the melt is slag removed. It is not thorough and forms a clamp in the ingot after casting.

Non-metallic inclusions destroy the continuity of the metal and are the source of cracks in ingots, plates and other products; the inclusions in the plate can also cause layers; the inclusions reduce the strength and elongation of the product; the inclusions will destroy the air density of the parts.

Non-metallic Inclusions Preventive measures

Keep the furnace charge clean and thoroughly remove the oil, dirt, dust and moisture in the original and auxiliary materials.

The furnace, launder and siphon box should be cleaned.

Carefully refine the slag removal, the refining temperature is at the upper limit of the casting temperature, and the standing time is guaranteed, and glass wire cloth is used in the flow plate.

Shorten the transfer distance as much as possible, establish good transfer conditions, close the open drop in the launder, flow plate, and funnel, prevent metal liquid level fluctuations, and use the same level of casting as much as possible.

Bake the tools thoroughly, and carefully clean the stove and other tools after casting.

Increase the casting temperature to increase the fluidity of the metal and make the slag float.