Molten aluminum runner system is an important part of any foundry. The well-designed launder system can promote the smooth and efficient operation of casting workshop, and the rapid transfer between casting workshops is very important. Clean, low turbulence runner plays an important role in the production of high quality products.

The size and grade of the runner system can meet the required conveying and/or casting capacity.

Functional components and accessories may include laser cleaning level control systems for (semi) automatic melt transfer and automatic casting operations, advanced metal probes for spill safety, and cleaning fluid thermocouples for fine-tuning molten metal temperatures during casting.

The launder runner system is very important to the quality and energy saving effect of molten aluminum metallurgy.

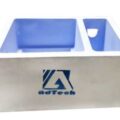

The liner of the launder system is made of high quality medium density fused silica refractory and pre sintered at 800 ° C prior to assembly. It has high aluminum resistance, low thermal conductivity, low shrinkage and high strength.

The ceramic launder cover can be used to reduce the heat loss by more than 50%, and the chute heating unit can be installed to minimize the temperature of the chute, thus reducing the tapping temperature of molten aluminum and protecting some highly flammable alloy elements.

Launder runner systems are available in various shapes, such as DC tanks, elbows, tees and cross mounting. They can be combined and used flexibly according to different site conditions.

Advantages of Molten Aluminum Runner System

1. It does not react with molten aluminum at working temperature.

2. Ultra high volume stability and resistance to thermal and cold shock, reducing the maintenance of the joint.

3. The liquid aluminum is not sticky, and the solidified shell is easy to remove.

4. Anti-corrosion, firm and durable.

5. Easy to transport and install; once broken, it will float on the molten aluminum, easy to remove.

6. Prevent aluminum melt from absorbing moisture and increasing hydrogen content without polluting aluminum melt.

7. The molten aluminum runner system has good nano thermal insulation layer and low shell temperature.