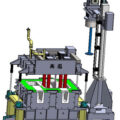

Molten aluminum degassing machine is a kind of on-line degassing equipment. Its design and production are carried out independently. It is used for the degassing and purification of molten aluminum.

The degassing box is cast and sintered with high strength imported castable, which has good thermal shock resistance.

The insulation layer outside the box is made of high-quality imported nano board, light fiberboard and other materials, with good thermal insulation performance.

The box cover and light casting are cast and sintered.

Working Principle of Molten Aluminum Degassing System

AR and N2 gases are blown into the bottom of the aluminum melt, and are completely chopped up by the impeller to form dispersed bubbles, so that the liquid aluminum is completely in contact with pure AR or N2 gas.

According to the principle of pressure difference and surface adsorption, when bubbles rise, hydrogen and oxide slag can be adsorbed, and scum will be formed on the surface, and hydrogen will be discharged through the belt to achieve the purpose of hydrogen and slag removal.

Russ aluminum company introduced the advantages of the molten aluminum degassing machine after use, and recommended the degassing unit manufacturer Adtech to other aluminum plants in Russia.

1. The cabinet is well sealed and evenly distributed.

2. Imported high-quality special high-strength composite casting material, low thermal conductivity, good insulation performance of the box body, and the temperature of the outer wall of the box ≤ 60 ℃.

3. It has excellent fire resistance, high temperature resistance, impact resistance, corrosion resistance, small thermal expansion and cold shrinkage.

4. High degassing efficiency and stable effect.

5. Excellent resistance to aluminum water penetration, no adhesion to aluminum, no pollution to aluminum liquid.

6. High strength, corrosion resistance, long service life (more than 24 months).

7. Man machine interface control, easy to operate and more humanized.

8. The degassing box design can be provided according to customer requirements.