Molten aluminum ceramic filters filtration is the most effective way to remove non-metallic slag in molten aluminum. In the casting of 6063 aluminum alloy, it is usually filtered with multi-layer glass cloth or foam ceramic filter plate. In order to ensure that the molten aluminum can be filtered normally, the molten aluminum should be removed from the surface scum before filtering. Because the surface scum can easily block the filter screen of the filter material, it cannot be filtered normally. The easiest way is to set a launder dam in the launder.

During the casting of 6063 aluminum alloy, turbulence and rolling of molten aluminum should be avoided as much as possible. Do not use tools to easily stir the molten aluminum on the launder and distribution plate, and let the molten aluminum flow into the mold smoothly under the protection of the surface oxide film. The tool agitates the molten aluminum, and the liquid turns to rupture the oxide film on the surface of the molten aluminum, causing new oxidation. At the same time, the oxide film is rolled into molten aluminum. Studies have shown that the oxide film has a strong adsorption capacity, it contains 2% of water. When the oxide film is contained in the aluminum liquid, the water in the oxide film reacts with the aluminum liquid, causing hydrogen absorption and slag inclusion.

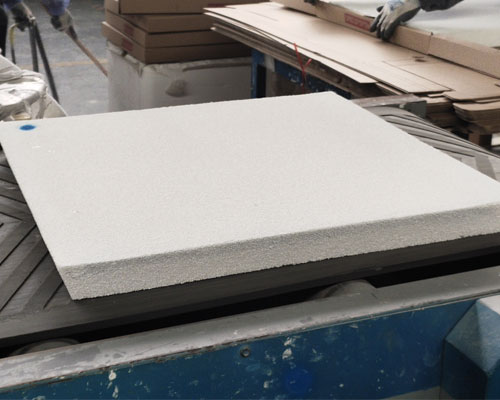

Alumina ceramic foam filters are mainly used to filter aluminum and aluminum alloys in foundries. Because of their excellent resistance to molten aluminum corrosion and corrosion, they can effectively remove inclusions, reduce trapped gas and provide laminar flow, and then the filtered metal is significantly cleaner. Clean metal can produce higher-quality castings, fewer waste products, and fewer inclusions, all of which help increase profits.

These inclusions are the main source of quality problems in castings. The alumina ceramic foam filters can remove molten aluminum, refractory waste, solid refractory alloys, impurities in sintered ore, eliminate turbulence, reduce casting porosity, and improve casting quality when casting products.

AdTech helps you meet the increasing demand for quality, providing ceramic foam filters and online degassing filtration equipment.

Molten Aluminum Ceramic Filters Advantages

- The aluminum alloy casting filter eliminates the turbulence in the metal flow, makes the metal flow smooth, and avoids spraying, splashing and collapse.

- Improve fluidity, castability, workability, output and cost-effectiveness.

- Remove a larger proportion of fine particles, reduce waste and rework

- Low pressure loss.

- Provide consistent flow rate and capacity.

- Provide various sizes, shapes and holes.