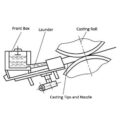

Install the molten aluminum castertip on the steel structure fixture, fix it with screws, then install the feed pipe and the front box, and check whether the joints are tightly connected to prevent leakage when the vertical plate is discharged. Put the assembled pouring system into the drying box, dry, and preheat. The furnace temperature is about 200 ℃, pre-drying for 2 hours, and stored in the 110 ℃ furnace, avoid inhaling water vapor. After preheating the molten aluminum castertip assembly and before installing it on the casting mill, all preparations should be made and the nozzle should be installed at the fastest speed to avoid heat loss and moisture inhalation.

Molten aluminum castertip is also called Tip Cavity, Nozzle Cavity, Casting Spile, Casting Tip, Feed Tip, Casting Nozzle.

Before casting and rolling production, take out the preheated molten aluminum castertip from the drying furnace, and check whether the feed nozzle is deformed after preheating and whether the components are tightly connected. Place the repaired molten aluminum castertip on the platform of the casting mill. After adjusting the position of the nozzle on the platform, fix it firmly. The casting nozzle is transferred between the two casting rolls through a hydraulic transmission system, and the relative position and gap between the feeding nozzle and the roll are carefully adjusted. Generally, the gap between the two end ears and the drum is 0.15 to 0.30 mm, and the gap between the feed nozzle and the drum is 0.3 to 0.5 mm. Local mutual contact or too large gap is not allowed. Install the ceramic launder between the CFF filter box and the front box, and check whether the slag box before and after the casting machine is connected with aluminum melt and aluminum chips, and whether various operating tools are complete.

Generally speaking, the thinner the plate, the higher the casting and rolling speed. Despite the thin plate, the hourly output is still high. However, the higher the casting speed, the stricter the required casting and rolling process parameters, especially the temperature fluctuation range of the front box should not exceed ±2℃, the liquid level fluctuation of the launder should not exceed 3 mm, and the liquid level of the front box The fluctuation must not exceed ±1 mm. In the casting and rolling process, if the temperature is too high, the casting speed should be reduced, otherwise the speed should be increased. During the steady rolling process, the speed should be adjusted slowly.