Al2O3 ceramic foam filter is just developed as a new type molten aluminium filter to decrease casting flaw in recent years. Alumina ceramic foam filter has the characteristics of light-weight, high mechanical strength, large specific surface areas, high porosity.

In industrial applications, filter materials are often chosen according to cost as well as their processing and thermomechanical properties, but rarely in terms of their behavior during filtration, which is largely due to there being insufficient information available on the influence of filter materials and surface quality on filtration behavior. In this study, the manufacture of functionalized Al2O3 nanofilters was investigated, along with their filtration performance in short- and long-term filtration trials. In addition, sessile drop tests were performed to measure the contact angle of the nanofunctionalized materials, and yielded an approximately 10 deg (11 pct) higher contact angle for nanocoated materials sintered at 800 °C and 1250 °C than for those sintered at 1600 °C and an approximately 23 deg (23 pct) higher contact angle compared to surfaces without a nanocoating. The filtration mechanism was assessed by means of Porous Disk Filtration Analysis (PoDFA) and Liquid Metal Cleanliness Analyzer (LiMCA) monitoring systems, as well as by analysis of the used and infiltrated filters using Scanning Electron Microscopy and Energy Dispersive X-ray analysis (SEM/EDX) technology. Both short-term and long-term filtration trials showed that the filtration behaviors of the reference and nanocoated filters were comparable. It was therefore determined that nanocoating of such filters with Al2O3 does not provide any improvement with regard to filtration performance.

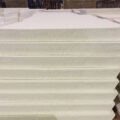

Alumina ceramic foam filter molten aluminium filtration is widely used in foundries and cast houses, it has excellent resistance to attack and corrosion from molten aluminum. Ceramic Foam filter (CFF) can effectively remove inclusions, reduce trapped gas from liquid aluminum and provide laminar flow, and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

Ceramic Foam filter is designed for filtering impurities from molten Iron & Alloy, nodular cast iron castings, aluminium castings and malleable castings, etc. It has excellent thermal shock resistance, erode resistance, high-performance.