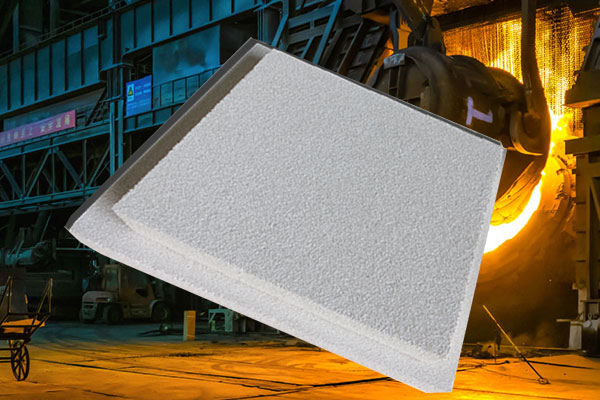

Molten aluminium Ceramic Filter is the most effective and reliable method to remove non-metallic inclusions from aluminum melt. It is also the most effective filtration method.

The deep bed filter is large in volume, and it is time-consuming and laborious to install and replace the filter medium, so it is only suitable for the production of single alloy in large quantities.

In this device, liquid aluminum flows downward and a vent plug is added in the center of the bottom of the device to replenish the inert gas. The liquid aluminum riser above the exhaust plug constitutes a gas lift pump with the adjustable metal level at the outlet. The aim is to make more efficient use of the filter ball while improving filtration efficiency. The device is small, compact and easy to fill, empty and move.

Corundum tube filters high efficiency, but the price is expensive, the use is not convenient, in Japan more applications. Southwest Aluminum developed corundum tube filters in the 1980s, but due to unstable assembly quality and other reasons, the filter effect is unstable, and it was no longer used in the 1990s. In recent years, technology has been further developed.

On the contrary, Molten aluminium Ceramic Filter is widely used worldwide because of its ease of use, good filtration effect and low price.

More than 50% of aluminum alloy melts in developed countries are filtered by foam ceramic filter plates.

Technology is advancing rapidly. In order to meet the requirements of high quality products for melt quality, the aperture of the filter plate is finer.

AdTech China’s molten aluminum Ceramic Filter has grown from 20, 30, 40, 50ppi to 60, 70ppi, and there are many new varieties to choose from.

For high quality products, developed countries generally use two-stage ceramic filters. The front stage filter plate aperture is coarse, the rear stage filter plate aperture is fine, such as 30/50, 30/60PPI, even 40/70 configuration, southwest Aluminum also uses 30/50PPI two-stage foam ceramic filter plate, used to filter double zero aluminum thin, PS plate base, can materials and other melt. Self-designed and manufactured secondary insulation filter box has been installed with a filter plate can produce continuous melting for 7 times, greatly reducing the cost of filtration.