The purpose of molten Alu purification is to remove the gas (hydrogen) and solid impurities (alumina) in the aluminum liquid. Purification of molten aluminum requires the use of a substance that can separate the alumina from the molten metal and drive hydrogen into the molten pool, but does not dissolve in the molten aluminum itself. This substance is called fluxes.

The original oxide film and corrosion products of aluminum material are important sources of slag and inclusions in the melt. The greater the ratio of the surface area to the volume of the aluminum material, the greater the oxidation tendency, and the greater the continued oxidation and smelting loss of the metal during the melting process.

When the thin and shredded waste is pre-packaged and then put into the molten aluminum, although the chance of contact with the air can be reduced, because the waste contains many air gaps, it will float on the surface of the molten aluminum after being put into the furnace and will not sink easily. The expected effect of isolating the air is not satisfactory, so it should be melted into ingots or melted into aluminum before putting in.

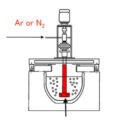

The oxide film and impurity particles suspended in the molten aluminum are difficult to be completely removed in a furnace with a wide-open surface. The effect of applying the flux with the powder spraying machine is better, but it is still difficult to achieve the purpose of comprehensively purifying the molten aluminum. Therefore, in addition to using the flux in the large-capacity furnace to remove some contaminated impurities, the modern melting and casting workshop also uses an online purification device outside the furnace, so as to completely remove remaining gas and slag inclusions in molten aluminum.

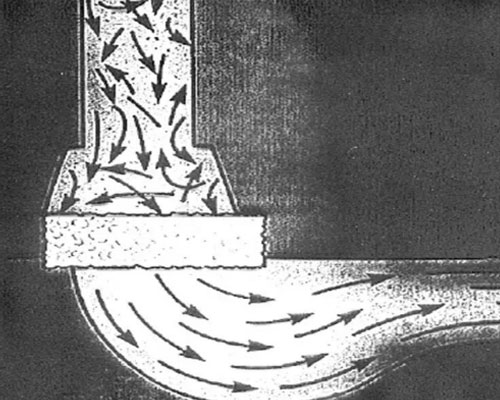

The principle of the molten aluminum purification device outside the furnace is to allow the molten aluminum to fully contact the inert gas in a small purification furnace equipped with a heater, so that the hydrogen present in the molten aluminum diffuses into the inert bubbles with zero hydrogen partial pressure and escapes. The solid slag suspended in the aluminum liquid will also be adsorbed on the surface of the bubbles and be removed together.

After online molten Alu purification treatment, the hydrogen content of molten aluminum can be reduced to half of the original value. Non-metallic inclusions with a particle diameter below 50μm can be removed by 50%, and that above 100μm can be removed by 90%. Adding 0.5%~3% Cl2 in the inert gas can increase the hydrogen removal rate from 50% to 65%, and can also remove 60%-75% of Na and Li, which is good for the production of aluminum-magnesium alloys.