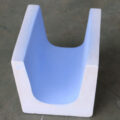

The metal casting launder system includes a flow cell base, a flow cell measuring wall integrated with the flow cell base, and a flow cell arranged above the flow cell base.

At least two clamping grooves are arranged inside the measuring wall of the flow cell, each clamping groove and the sliding groove are arranged perpendicular to each other, and a filter plate is installed in the clamping groove.

When in use, the ceramic foam filter plate is easy to replace, and the effect of purifying molten aluminum is remarkable. The filter plates are installed in slots on the bottom and side walls of the flow cell. It can filter impurities and purify molten aluminum. It can further improve the purity of molten aluminum and meet the quality requirements of casting high, thin and sharp aluminum products. Safe and reliable, convenient and quick to replace.

Adtech China provides high silica metal casting launder for various aluminum casting industries. The surface of the product is smooth, non-stick aluminum, corrosion and high temperature resistance.

Features: low thermal conductivity, excellent thermal and chemical stability, without adhesives and corrosive substances.

Application: Vacuum forming products of materials and coatings filled with fiber casting materials.

High silica is a kind of aluminosilicate, characteristic: colorless crystal.

Dissolution: insoluble in water.

High silica runner is an excellent high temperature resistant runner lining for aluminum and aluminum alloy melt runners. It is in direct contact with the melt and has excellent thermal insulation, thermal shock resistance, compressive strength and resistance. The aluminum melt will not disintegrate or peel off easily after washing for a long time. It reduces the secondary pollution of the aluminum melt in the conveying chain link of the guide groove to a minimum and has a long service life.

As the market changes, the development trend of the electric heating tank industry will continue to develop.

The operation and management of the enterprise has begun to transform from the single goal development in the past to systematic and scientific management.

How to understand the development and market changes of the liquid aluminum flow tank industry from a professional perspective, and how to effectively manage all aspects of the enterprise with scientific methods, will become the primary issue for the future survival and development of the enterprise.

Taking the high temperature DC tank industry as the starting point, through the comprehensive analysis of the characteristics and statistical data of the convection tank industry, the development overview and basic characteristics of the high temperature DC tank industry are determined.

Use scientific methods and models to help the company grasp market trends and clarify the competitive trends in the aluminum liquid flow tank industry.

On this basis, targeted analysis is carried out for the management problems encountered in the development of the enterprise, and effective solutions and methods are provided for the enterprise to solve the resistance in the operation.