Melt filtration is the most effective and reliable way to remove non-metallic inclusions in aluminum melt. There are many kinds of filtration methods, and the most effective and most effective ones are tubular filtration and foam ceramic plate filtration.

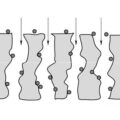

The corundum tube filter has high filtration efficiency and can effectively remove small non-metallic inclusions in the melt. It is suitable for the filtration of aluminum alloy melts such as forgings, cans, double zero foils and aluminum profiles with high metallurgical quality requirements. But the use of corundum tube filtration is expensive. The filter is equipped with several corundum tubes. The melt passes through the small and tortuous micropores of the ceramic tube. The impurities in the melt are blocked, settled, and the surface of the medium absorbs the impurities and van der Waals force. The impurity particles in the body are filtered out.

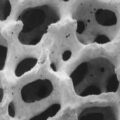

The foam ceramic filter plate is widely used at home and abroad because of its convenient use, good filtering effect and low price. In developed countries, more than 50% of aluminum alloy melts are filtered by foam ceramic filter plates. The ceramic foam filter plate is generally a filter with a thickness of 50mm and a length of 200-600mm, with a porosity of 0.8-0.90.

AdTech has been committed to the research, development, production and marketing of bonded ceramic foam filters (CFF) for aluminum alloy casting. AdTech’s ceramic filter technology has been widely recognized by the market and can be used to produce a variety of series of aluminum alloy products, such as PS skirting for printing, canned materials, flexible packaging materials, railway vehicles, aerospace products, cables, wires, etc. High-precision filtration and purification of cast aluminum alloy.

The ceramic foam filter adopts the adsorption principle, which can effectively remove the large inclusions in the molten aluminum and effectively adsorb the small inclusions. No debris falls off, effectively reducing the pollution of molten aluminum. Excellent thermal shock resistance, improve the erosion resistance of molten metal. Automated production, 3 calibration procedures, precise dimensions.