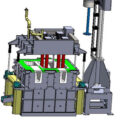

Launder for Casting is an important part of the aluminum casting process. After the molten aluminum in the holding furnace is processed in the furnace, it is transferred from the holding furnace to the online refining device, and then enters the casting machine through the launder for casting. Since the liquid level control accuracy is very high, reaching a control accuracy of ±1mm, the required accuracy of the molten aluminum conveying process in the holding furnace is very high. In order to ensure that the molten aluminum level of the holding furnace can be accurately controlled during the conveying process of the molten aluminum, the holding furnace adopts a tilting structure, and two hydraulic cylinders are used to tilt the holding furnace at a certain rate. While the holding furnace is tilting, the molten aluminum enters the launder for casting and gradually enters the downstream production process. By controlling the tilting rate of the holding furnace, it is possible to precisely control the liquid level in the molten aluminum transfer trough and the liquid level required by the casting process.

Due to the tilting structure, the structure of the related parts of the holding furnace needs to meet the requirements of tilting. Including the inverted launder from the smelting furnace to the holding furnace, the ceramic launder from the holding furnace to the online refining equipment, and the holding furnace flue, all need to meet the requirements of the holding furnace tilting, and the stability of the structure can be maintained during the tilting process. In this way, part of the structure of the flue remains sealed during the tilting process, no flue gas leaks, and refractory materials in the flue will not be damaged.

During the tilting process of the holding furnace, there is no molten aluminum in the inverting furnace launder for casting. The holding furnace can be separated from the ceramic launder during the tilting process, but the connecting part must be ensured not to be damaged. In order to make the inverted furnace launder move flexibly during the tilting process of the holding furnace, while not damaging the refractory material in the inverted furnace launder. The refractory material in the connecting part of the inverted launder of the smelting furnace and the holding furnace is designed as a slope. When the holding furnace is tilted, the slope part is easy to separate and will not damage the refractory. When the holding furnace returns to its original position, the slope part is re-compressed and connected, and the molten aluminum will not leak from the joint during the furnace down.

During the tilting process, the tilting orifice of the holding furnace must ensure that the molten aluminum does not leak out and ensure the molten aluminum transmission process. In this way, the design of the tilting orifice of the holding furnace can not only rotate with the tilting of the holding furnace, and the part of the conveying chute connected with the tilting of the holding furnace, while the part of the conveying chute is fixed, ensuring that the aluminum liquid is tilted from the holding furnace into the metal transfer runner system, and then transferred to the online refining device and casting machine.