Above the water-cooled crystallizer, install a heat-preserving cap made of insulating film material, also called hot top cap, pouring cup. The requirements for the hot top cap are no chemical reaction with molten aluminum, no moisture absorption, no oil absorption, no wetting to molten aluminum, high-temperature resistance, good insulation performance, thermal shock resistance, good strength, easy replacement and maintenance, and low price.

Traditional Hot Top Crystallizer

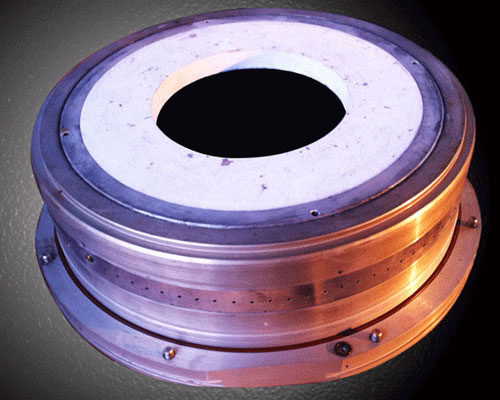

Traditional hot top molds include hot caps, heat-insulating gaskets, molds, graphite rings, etc. The outer shell of the hot top cap is welded with a 3 mm thick iron plate, and the inner lining is made of 4-5 mm asbestos board or aluminum silicate felt. The height of the hot cap is 80-100 mm. If the heat cap is too short, turbulence will occur, and it is inconvenient to control the liquid level. When the metal static pressure is too high, metal nodules and aluminum leakage are likely to occur. At the same time, there is a tendency to increase the segregation floats, which is not conducive to the improvement of surface quality.

During casting, the control metal level is about 20 mm away from the upper edge of the hot cap. The inner diameter of the hot cap is the same as the inner diameter of the aluminum silicate heat-insulating gasket, which is 3~5 mm smaller than the graphite ring. The heat-insulating gasket is 5-8 mm thick aluminum silicate. Cut fiber felt. Because the aluminum silicate felt has good thermal insulation properties, it can prevent the crystallization area from developing upward, and it has a certain degree of elasticity. It does not infiltrate the liquid aluminum and is easy to achieve sealing. The protruding distance from the inner side of the overheated sealing gasket to the mold should be as short as possible, generally less than 3-5 mm.

In order to reduce the impact of the boss on the surface of the ingot during production, an inclined plane can be used, with an inclination angle of 45 degrees from the horizontal. The mold is lined with a graphite ring, and an 8mm high aluminum table is left under the graphite ring to meet the needs of the multi-mold casting base ascending. The inner diameter of the aluminum table is 1~1.5 mm larger than the inner diameter of the graphite ring.

The total height of the mold is equal to the sum of the height of the graphite ring and the height of the aluminum table. The height of the crystallizer is the height of the effective crystallization zone, which is generally controlled at 15-50 mm in production.

The height of the graphite ring is an important parameter of hot top casting. If the height of the graphite ring is too small, the crystallization zone will rise and go deep into the sealing and heat insulation ring, which will easily cause pull marks and cracks on the surface of the ingot. The graphite ring is too high, the contact area between the metal in the semi-solidified state of the casting edge and the graphite ring is large, and the surface of the ingot is not smooth. The inner diameter of the graphite ring plays the role of sizing. The thickness of the graphite ring should be as thin as possible, but considering the strength of the graphite itself and meet processing needs, the thickness should be 4 mm. The requirements for graphite rings are good thermal conductivity, lubricity, sufficient finish, and strength.

New Hot Top Crystallizer

When using multi-mold hot-top casting, the mold is installed under the water tank pouring platform, and the hot cap is located above the pouring platform to form a unified hot-top distribution launder. The side of the mold is open to realize multi-mold casting. Currently commonly used are fused silicon precast molded parts, vacuum-formed aluminum silicate fiber refractory products, and calcium silicate prefabricated refractories reinforced with graphite fibers as the main component.