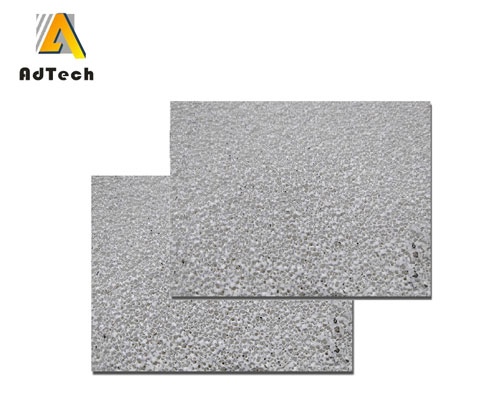

Honeycomb filter material has natural chemical adsorption (affinity) ability to oxides, and absorbs impurities (including particles smaller than the pore size) in the molten metal on the inner wall of the hole, which improves the filtering effect. The advanced extrusion production process makes the ceramic filter with a unique square and triangular design, which increases the contact area with the ceramic, improves the filter’s ability to adsorb and capture small impurities, and has a better filtering effect than the non-extruded filter: The liquid metal flows smoothly; improve the pouring speed and continuity; reduce the casting scrap rate; improve the casting mechanical properties: extend the service life.

Foam ceramic filter products are made by a special process, with foam-like porous structure ceramic products: it has stable chemical properties, high strength, high temperature resistance, good thermal shock resistance, large specific surface area, etc. Many advantages are widely used in metallurgy, casting, environmental protection and other fields.

The casting structure filters out the inclusions in the casting: reduces the gas in the casting: reduces the degree of turbulence during the filling of the metal flow: reduces the surface defects of the casting. Significantly reduce the scrap rate of castings. Casting performance increases the casting’s compressive sealing: enhances elongation and tensile strength: improves the surface finish of the casting. Casting performance improves the fluidity of the molten metal, and increases the filling and filling capabilities of the casting.

The pouring system design simplifies the pouring system design. The length of the cross-runner is reduced, and the casting process is improved. Casting processing reduces the processing time and tool damage: improves the surface quality of casting processing. Its use can reduce waste by 60-80%. The annual profit of filter users can reach ten million yuan. Uses and advantages The ceramic filter is to eliminate casting defects: the best purification function element to obtain perfect quality castings. It can be used for in-mold filtration of various liquid metals in casting production.

Advantages of Honeycomb Filter Material

1. Honeycomb filter material has a very high high-temperature working strength: thermal shock resistance and resistance to metal liquid flow impact. No slag or cracking during work: ensure the filtration quality of molten metal

2. It has extremely high normal temperature strength and resistance to mechanical impact. No breakage or damage during use and transportation: it greatly facilitates the operation of the filter.

3. Has a very significant filtering effect. Far higher than the filtering effect of the fiber filter. Its remarkable filtering effect is related to the filtering mechanism of speed criterion.

4. It can effectively reduce the turbulence of the molten metal brought by pouring: make the filling smooth and avoid the casting surface defects.

5. It has a large metal flow rate and stable flow rate (different from the foam ceramic filter whose flow rate gradually decreases as the number of trapped inclusions increases). Even when melting

In the case of a large amount of inclusions in the metal: normal use will not cause clogging of the filter.

6. It has high chemical stability, is not affected by the acidity and alkalinity of the liquid metal, and does not change the chemical composition of the liquid metal.

7. With very high dimensional accuracy, it can be used in the production line for automatic placement of filter sheets.

The use performance of the ceramic filter is obviously superior to the fiber filter. The filter effect of the fiber filter is to reduce the turbulence of the metal liquid: the high temperature strength and other properties are not as good as the ceramic filter. The ceramic filter is considered by the foundry manufacturer from the aspects of practicability, reliability: quality and price: the best filter material used to eliminate defects in castings: mullite, cordierite, high aluminum, carbonization Silicon etc.