Regarding the relevant knowledge of high-temperature tap cones, everyone knows that there will be a lot of high-temperature smelting in industrial production, but the high-temperature liquid after high-temperature smelting will enter the mold through the laundering and form products commonly used in our daily life. Have you noticed here? What about a word? right!!! That is the launder, here because there are many paths of the launder, and the launder cannot be replaced frequently, so a kind of material-“high-temperature plug” is extended, and the high-temperature plug is divided into several categories: insulation cap, plug Sleeve, aluminum silicate high-temperature plug, aluminum water plug, aluminum silicate plug, so it is well understood that one of its biggest uses is to change the path of high-temperature liquid in the launder, which is commonly used in industrial production Words – flow control.

The high-temperature plug produced is made of high-alumina fiber, which is changed from the original hand-made process to the vacuum suction filter automatic equipment forming process, with high production efficiency, high-quality stability, and a yield of 99%; it has a uniform distribution of plastids, hardness Higher than ordinary tap cones, tight plugging, non-sticking to aluminum and no slag formation, used for metal liquid control and closure of boxes and kilns.

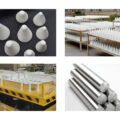

Show a few pictures to help you understand the details of the high-temperature tap cone more intuitively:

Use of high-temperature plug:

High-temperature tap cone

Iron cone

Product advantages: 1. Vacuum suction molding of high-alumina fiber, non-stick to aluminum and no slag; 2. Uniform distribution of plastids, good elasticity, tight plugging, and stable flow control;

3. High hardness, long service life.

tap cone