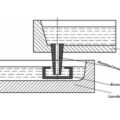

It can be seen from the principle of casting and rolling that the entire gating system is a “U”-shaped connector. The level of the liquid metal in the front tank determines the metal pressure at the mouth of the feed nozzle. The liquid level is not well controlled, and the casting process cannot proceed normally. In the casting-rolling zone, the supply of melt at the moment of solidification and the pressure required for holding are all controlled by the static pressure of the melt level in the front box. In principle, the higher the level of the liquid level in the front box, the better under the condition that the oxide film on the surface of the melt is not damaged. Because the melt in the liquid cavity has a strong pressure on the crystal surface at this time, it can not only ensure the continuity of melt solidification, but also obtain a dense structure.

If the liquid level of the front tank is low and the static pressure is small, it is manifested as insufficient supply of melt at the crystallization front, and holes are easy to appear at the center of the cross section of the strip or cracks or hot spots appear on the surface of the strip. If the liquid level of the front box is very low, the melt will not flow into the cast-rolling zone, but will stay in the feed nozzle cavity for a little longer, and condensation may occur, which will destroy the continuity of the cast-rolled strip and show up. Face hole. If the liquid level is too high, the static pressure of the melt is too large, which is easy to cause the surface of the cast-rolled strip to be ridged, or the surface of the strip is pressed with a broken oxide film, which causes the oxide film folding defect and reduces the surface of the strip quality. If the melt level in the front box is too high and the gap between the feed nozzles is too large, the oxide film will easily break, and the melt will enter the gap between the nozzle rolls, making casting impossible. The adjustment of the liquid level of the front box is mainly to adjust the relationship between the static pressure of the front box and the surface tension of the liquid film, and adjust it under the condition of maintaining a balance.

In actual production, the liquid level of the front tank is difficult to measure. Generally, a reference line is found on the casting and rolling mill, and the value is determined by the distance between the reference line and the oxide film. For example, for a two-roll horizontal casting-rolling mill, based on the horizontal line connecting the centers of the two rolls, the height of the front box liquid level higher than this line is indicated by +, and the lower than this line is indicated by -. In a two-roll horizontal or inclined cast-rolling mill, the horizontal line of the center of the gap between the two rolls is usually used as the reference, and the distance from the liquid level to this line is the liquid level of the front box. Therefore, in actual production, the liquid level of the front box is relative to the centerline of the casting and rolling between the two rolls. For a two-roll inclined cast-rolling mill, the front box liquid level control is 10-20mm higher than the cast-rolling centerline.