Front Box for Aluminum Casting is also called flow control box, tundish. The temperature of front box for aluminum casting is also called pouring temperature. In production, thermocouple is often used to measure liquid metal temperature in front box to control pouring temperature. The stability of temperature has a direct impact on the constant crystallization rate in the process of casting and rolling. Therefore, the fluctuation of front box temperature should be reduced as far as possible to ensure a stable liquid level height in the front box, so as to ensure the production of qualified cast rolling plate with longitudinal thickness difference.

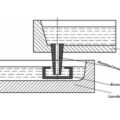

In the continuous casting and rolling method, hot top accessories such as flow control box, float, flow trough, casting nozzle plate, etc. They can well control the flow of molten aluminum. Tundish is used between the split flow and flow channel of the matching casting nozzle. It is used for the casting and rolling forming and size control of aluminum plates, aluminum strips and aluminum foils. AdTech hot top accessories adopt high-silicon molten material forming technology, corrosion resistance, non-stick aluminum, no slag.

The liquid level of the front box for aluminum casting provides the flow rate and pressure for the liquid metal at the moment of crystallization in the casting and rolling area, so as to ensure the continuity of metal crystallization and obtain a dense structure, which is beneficial to the quality of cast rolling plate.

If the liquid level is low, the static pressure will be reduced, and the flow rate will be insufficient, which can not meet the requirements of casting and rolling speed, and hot strip will appear easily. When the liquid level is high, the static pressure of liquid aluminum increases, and the crystallization speed can’t keep up with the rolling speed, resulting in more liquid extrusion from the gap between the ears, and the ears are washed out together, resulting in a large amount of liquid aluminum flowing out, resulting in production interruption.