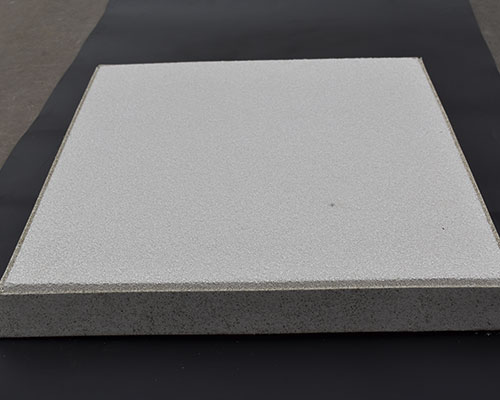

The foundry ceramic foam filter production is made of non-stick aluminum material, it has the characteristics of non-stick aluminum, and the product is white or milky white. The foundry ceramic foam filter is suitable for the purification process of producing high-quality and high-demand aluminum and aluminum alloy. Through physical adsorption and chemical action, it can effectively remove all kinds of oxidation inclusions produced in the aluminum smelting process, thereby reducing casting defects, improving casting quality, and providing high-quality materials for the next step of deep processing.

The aluminum liquid ceramic foam filter plate should be preheated before use, and the filter plate should be completely sealed in the plate filtering unit to ensure that all the aluminum water passes through the filter plate, and the total amount of filtration must not exceed the specified limit. If the slag content in the molten aluminum is too high, it should be adjusted by multi-piece filtering or reducing the throughput.

Foundry Ceramic Foam Filter Production Process

(1) Foam cutting—(2) Mixed ingredients—(3) Grouting—(4) Drying—(5) Grouting—(6) Drying—(7) Burning—(8) Inspection and packaging

Auxiliary ingredients were added according to the optimally designed ingredient formula, and the organic foam precursor dipping method was used to develop a high-performance ceramic filter plate for the filtration and purification of aluminum liquid.

The porosity of the foam with modifier is above 90%, and the compressive strength can reach up to 2 MPa. Taking into account the shape stability of the material, adding about 8% bentonite to the basic components can make the modification effect of the ceramic filter plate reach the best state.

The higher the crystallinity of the foam ceramic matrix material, the higher the strength of the material at room temperature.

The three-dimensional network structure and the organic foam sponge with connected pores are used as the carrier, and it is invaded into the special ceramic slurry with thixotropy, and a special roll extrusion process is adopted to make the ceramic slurry evenly spread on the skeleton. It is dried and cured and then fired at high temperatures.