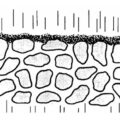

The foam ceramic filtration mechanism is generally described as diffusion interception and inertial collision interception or screening, sedimentation and deep bed filtration.

The State Key Laboratory of Tsinghua University established a three-dimensional physical model and a two-phase flow model for the filtration mechanism of foam ceramics, and carried out simulation calculations, which is very helpful for us to study the filtration and purification of molten aluminum.

However, the process of filtering and purifying molten aluminum by ceramic foam is very complicated, and it is also a complex process of high temperature physical chemistry and metallurgical dynamics. As for screening collision, settlement, interception and filtration, it is better to understand.

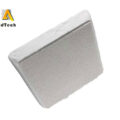

Correctly choose Foam Ceramic Filtration Mechanism to improve the cleanliness of aluminum melt.

The selection of the ceramic foam filter plate is first determined according to the impurity content in the aluminum melt, the melt transfer flow rate and the quality requirements of the final casting product.

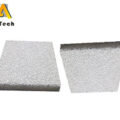

①With a large amount of impurities, the quality of the casting products is average. A foam ceramic filter plate with a larger mesh can be selected, and a glass cloth coarse filter is added in front of the filter plate. At this time, it is important to use glass cloth to filter the semi-continuous casting first. It can intercept the slag when the eye is opened and the slag washed down by the launder to prevent the filter plate from clogging.

②The quality requirements of the casting products are high, and the new type of foam ceramic filter with small hole mesh, that is, large mesh number, is selected.

E.g:

Fujian Ruimin Aluminum and Southern Aluminum produce aluminum foil blanks, Henan Mingtai Aluminum produces high-quality hot-rolled slabs, Northeast Light Alloy Processing Plant produces high-quality military aluminum, and Guangdong Zhongshan Hesheng Aluminum produces high-quality industrial profiles All the products adopt the second-generation Ceramic Foam Filter China produced by AdTech.

The most prominent is the use of 30ppi and 60ppi specifications of 305x305x50. 381x381x50, 432x432x50, 508x508x50 two-stage filtration technology, to achieve the ideal cleanliness, and obtain good results.

The selection of Foam Ceramic Filtration Mechanism is based on the flow rate and total throughput of the melt. If the flow rate is large, the total throughput is large, and the filter plate has small holes, a larger size is used.