Foam ceramic filters for metal casting have been widely used in aluminum foundry because of their good economic benefits and strong impurity removal function. The ceramic foam filter can effectively intercept the inclusions in the liquid metal, thereby improving the quality of the casting. The ceramic foam filter for metal casting separates the inclusions in the liquid casting alloy through three physical and chemical actions to achieve the effect of purifying the molten metal.

Foam Ceramic Filters for Metal Casting Filtration Mechanism

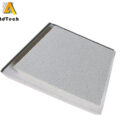

Filter cake mechanism: The complex foam ceramic structure can effectively block the slag mechanically. When the molten metal passes through the ceramic foam filter with a complex structure, the mechanical separation will filter out the inclusions larger than the pores on the filter surface and deposit them on the liquid metal inflow end of the filter, becoming a part of the filter. As the accumulation of inclusions on the surface of the filter increases, a layer of “filter cake” is gradually formed, which further narrows the flow channel of the molten metal. Therefore, the surface of the new filter media can filter out finer inclusions. At the same time, the inside of the medium also has a filtering effect, and some of the many small holes penetrating the ceramic body show tiny slits, and some have dead corners. These areas with different changes are possible locations for intercepting inclusions, and there is also a “filter cake” effect inside the filter.

Surface effect: When the molten metal flows through the ceramic body with complex structure, it is divided into many small streams, which increases the contact area and probability of contact between the central debris of the molten metal and the filter medium. Because the surface of the filter is very small convex and concave surface, the size of the concave block is about 1~10um, which has the effect of electrostatic adsorption and adhesion to intercept the inclusions.

Rectification effect: When the molten metal flows through the ceramic foam filter, it is divided into streams of many small units, making the liquid flow tend to move in a laminar flow. When the molten metal is in a laminar flow state, since the density of the molten metal is much greater than the density of the inclusions, the inclusions have sufficient time to float up and remove.