Foam Ceramic Filters for Casting removes non-metallic inclusions in the aluminum alloy melt and adopts furnace flux treatment. The technology of ceramic foam filtration outside the furnace has long become an important means of purifying molten aluminum.

Reflected in the alloying, purification, and refinement processing technology of the smelting process. The smelting of aluminum alloy is the first step in the aluminum alloy processing process, and it is also a crucial link.

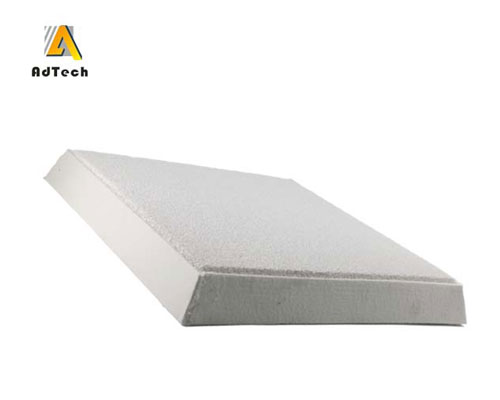

Foam Ceramic Filters for Casting is a kind of porous ceramic product with opening porosity as high as 80-90%, volume density only 0.3-0.6gcm”, with a unique three-dimensional network framework and interpenetrating pore structure.

The earliest foamed ceramic filter plate was developed by FRMollard and NDavison of Consolidated Alnminum in the United States in 1978 and used in the aluminum alloy pouring system. Their research results were published at the American Foundry Annual Conference in April 1980.

The Foam Ceramic Filters for Casting filter and remove impurities, which can significantly improve the quality of ingots and reduce the waste rate. Since then, the corresponding research and development of foam ceramic filter materials have been promoted in the metallurgical industry.

The production of ceramic foam filter (CFF) generally uses a three-dimensional network structure and connected pores of organic foam as a carrier, immersed it in a special ceramic slurry with thixotropy, and adopts a special roll extrusion process to make the ceramic The slurry is evenly spread on the skeleton of the carrier, but it is dried and solidified and then fired at a high temperature.

Purification Mechanism of Foamed Ceramic Materials

1. Through mechanical filtration such as screening inertial impact interception and diffusion interception, friction and sedimentation, the filtration efficiency is proportional to the mesh aperture of the foam ceramic. The smaller the mesh, the stronger the ability to intercept small particles.

2. Sedimentary layer or filter cake layer effect. With the deposition of particles in the melt and the crooked interconnected and uneven grid support walls, the ability to capture miscellaneous particles is improved.

3. The rough surface formed due to the gaps on the surface of the mesh frame increases the interface between the molten aluminum stream and the ceramic solid surface, which can promote the flow of particles in the molten aluminum stream to be more disordered, which is conducive to the capture and deposition of solid particles. .

4. Due to the microscopic cracks and pinholes on the surface of the mesh frame body, fluoride with strong affinity for Al2O3 particles is pre-deposited, which promotes a complete filter cake effect and strong chemical adsorption, and the ability to capture the remaining impurity particles is more Strong.