Regarding foam ceramic filter products, the development began in the 1970s. After more than 30 years of rapid development, the materials of the products are silicon carbide, zirconia, alumina, graphite, etc.; application areas include casting Steel, cast iron, cast aluminum, cast copper filtration. The ceramic foam filter can greatly improve the surface quality and performance of the casting.

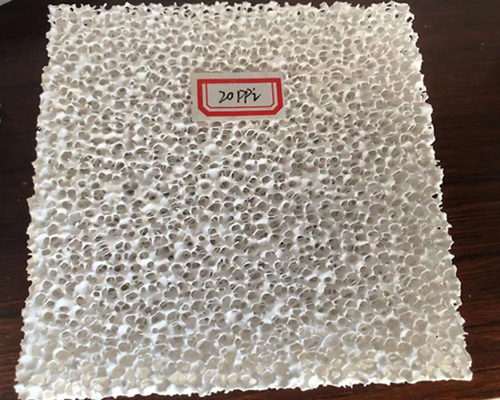

The ceramic foam filter adopts polyurethane foam as the precursor, dipped in refractory slurry molding process, and is a special ceramic product with a three-dimensional network structure after high temperature sintering. Classified by material: alumina, magnesia, silicon carbide, zirconia, carbon composite material; according to mesh density PPI classification: 10ppi, 15ppi, 20ppi, 25ppi, 30ppi, 40ppi, 50ppi, 60ppi.

Features of Foam Ceramic Filter Products

- It has a unique three-dimensional connected curved pore network skeleton structure and 80% to 90% open porosity.

- There are four filtration and purification mechanisms, namely: screening-filter cake-deep bed filtration mechanism, floating separation mechanism, deep filtration (physical adsorption) and rectification mechanism.

- It can efficiently filter out the large inclusions and most of the tiny suspended inclusions as small as tens of microns in the molten metal.

- Compared with the fire-resistant fiber filter and the straight-hole honeycomb ceramic filter, it has the characteristics of high refractoriness, high strength, good filtering effect and high filtering efficiency.

AdTech specially designed Ceramic Foam Filters are made of the basic raw material Aluminium Oxide. They are manufactured with porosities varying from 10 to 60 pores per inch (PPI).

AdTech Alumina Ceramic Foam Filter adopts the principle of adsorption to filter, which can effectively remove large inclusions in molten aluminum and can effectively adsorb small inclusions. No broken pieces fall, effectively reducing the pollution of molten aluminum. Excellent thermal shock resistance, improve the erosion resistance of molten metal. Automatic flow production, 3 calibration procedures, accurate size, and close fit with the filter bowl. Improve surface appearance and performance, and purify molten aluminum.