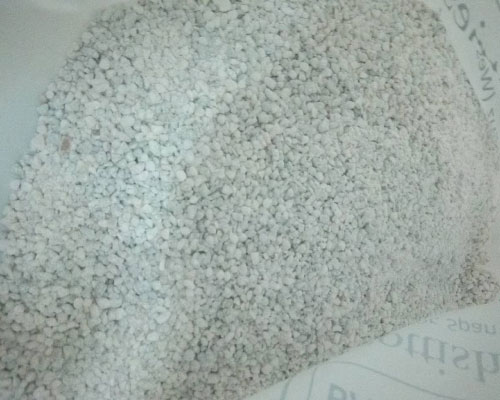

The AdTech flux for aluminum casting is usually added to the furnace, crucible, ladle during the melting, heat preservation or degassing of aluminum. The raw material quality of the flux, the adding method and the product form all affect the efficiency. The flux formulation will vary based on its use and other process variables (such as alloy and temperature).

In aluminum refining, fluxes are used to help remove impurities and change the fluidity of the melt. Once activated by the high temperature of the furnace, the flux will decompose and lower the melting point of all other materials in the crucible. As the refining process continues, the flux for aluminum casting will cause other materials to oxidize and further decompose.

The formation of alumina and the presence of non-metallic inclusions are an inherent part of the casting process and must be managed to obtain the highest quality castings. For many years, one of the skills of casters is to use flux to reduce alloy waste, control the formation of tin slag and remove impurities in the alloy, otherwise it will affect the quality.

In foundries, movement is part of the casting process, which can cause surface cracks, further oxidation and rapid surface film thickening. This thickening of the shell also wraps the unoxidized aluminum, leading to “wet slag” and wasting a lot of alloy. In a typical wet slag, only 20% to 40% of the alumina is alumina, and the rest is encapsulated aluminum. This can result in a reduction of 5% to 10% in the total amount of molten metal.

By forming a molten barrier layer on the surface of the alloy to reduce oxidation and hydrogen adsorption, and reduce the thickness of the slag shell, “covering” and “dust removal” fluxes can be used to solve these problems. Since the surface crust will not become thicker, these refining fluxes can reduce the amount of suspended liquid metal by 60%-80%.