The filtration ability of the filter to remove inclusions from molten aluminum mainly depends on the roughness of the openings formed in the aggregated mesh member and the configuration of the mesh member. Therefore, particularly in order to remove fine inclusion particles of about 10 to 25 μm, the aggregated mesh member needs to have 2 or more meshes per linear inch.

On the other hand, in order to manufacture an internal filter, aggregates such as ceramics are formed into a net shape and baked to obtain an aggregate net-like member. Then, the aggregated mesh member is impregnated with any one or more of the aforementioned coating compounds to coat its surface.

When an adhesive is used, the mesh member is impregnated with the adhesive and the paint in this order. Alternatively, it is impregnated with a mixture of coating compound and binder. In any case, due to the original physical properties of the coating compound and the binder, the impregnating material used to impregnate the mesh member exhibits a relatively high viscosity.

The higher the viscosity of the impregnating material, the finer the mesh of the aggregated mesh member, and the more difficult the coating process becomes. In particular, in practice, not only must the outer surface of the mesh member be completely covered, but also the inner surface of its opening (hole) must be completely covered. Even if these surfaces are located in the center of the mesh member, it is impossible to completely cover the entire mesh member.

Therefore, when the coating compound is applied to the internal filter, the coating efficiency with respect to the entire surface of the mesh member may be low, thereby reducing the efficiency of the internal filter to remove impurities. The volume of each filter unit and the weight of the filter unit. This low removal efficiency may prevent the internal filter from being used for the filtration of molten aluminum alloy.

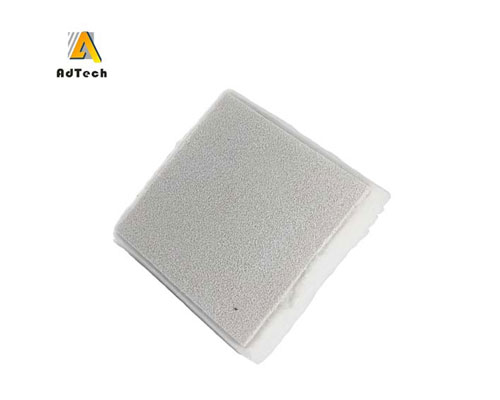

AdTech provides a molten Al ceramic foam filter for removing inclusions from molten aluminum alloys. The filter includes an aggregate mesh member made of a refractory material and a coating formed on the surface of the mesh member. The coating has the ability to soften at the temperature of molten aluminum or molten aluminum alloy.