The industry in the world continuously puts forward new requirements for the quality of high-tech products such as can blanks and PS plate aluminum substrates. Ceramic foam filters are required in aluminum processing and production, which remove non-metallic inclusions from molten aluminum and its alloys. Ceramic foam filters for cast alloys are the most effective way for molten metal filtration.

The basic requirements for filters for cast alloys are:

- The filter can effectively remove leek metal inclusions.

- The filter must guarantee the normal metal casting speed.

- The surface of the filter should be uneven, with certain chemical stability and good thermal shock resistance.

- When in contact with molten aluminum, it will not damage, burst, or pollute molten aluminum.

- Lower cost.

These conditions are neither independent of each other nor completely compatible. For example, if the passing speed of molten aluminum is increased, the filtering effect will be affected. The filters for cast alloys can reduce the resistance to the flow of molten metal by increasing its pore size and the number of holes, or by reducing the thickness of the filter mesh. Therefore, the design of the filter must consider its structure, flow resistance, and the best filtering effect and casting quality.

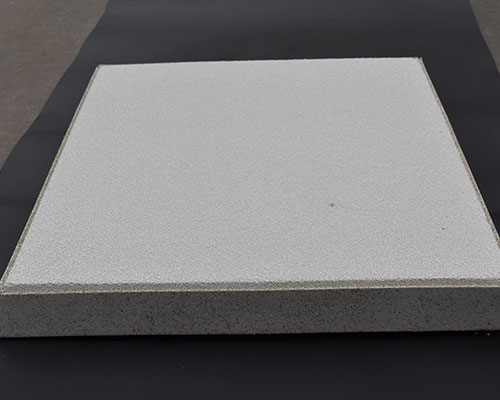

The ceramic foam material is a new type of material, which can be made into various sizes and shapes to meet the needs of filter characteristics and filtering effects.

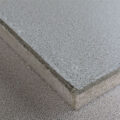

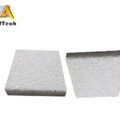

The ceramic foam filter (CFF) consists of a piece of open-cell ceramic foam with different thicknesses and cross-sectional areas. Typically, it will have an interconnected void of 85% by volume. The fineness of the filter manufacturing varies, usually 10, 20, and 30 PPI (pores per linear inch), and there is a tendency for fine pores (50, 60, 80 PPI). As the pore size decreases, the filtration efficiency and reliability of the filtration system will increase. Another interesting observation for filtering very clean metals is that the filter performs poorly for small particle sizes (15-30 m) compared to particles in the 30 to 60 m range.