Investment casting is the process of forming metal or metal alloy products (also called castings) by solidifying molten metal. Precision casting is an important method for producing high-quality precision casting metal products in various industries. Castings usually contain unwanted materials called “inclusions.” The generation of inclusions can be attributed to the slag or scum material mixed in the melt, or foreign matter from the mold, or pollution from the casting environment, such as dust and dirt. Inclusions in cast metal products are not conducive to the mechanical properties of the metal and may cause catastrophic damage under stress. Therefore, many industries, especially the aerospace industry, have established strict specifications to manage the presence and acceptable size of inclusions in castings. Filtration is a method used to filter impurities such as slag and dross from molten metal.

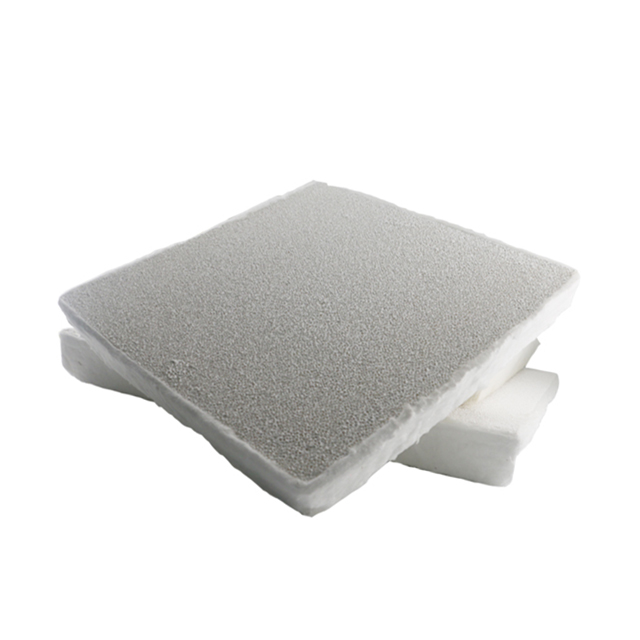

Ceramic foam filter is the most widely used filtration of molten metal, a kind of “porous ceramic body” made of various ceramic powders, and can separate external intermetallic inclusions from molten metal. The filter may be constructed of a ceramic material suitable for filtering molten metal. The ceramic foam filter can be coated or impregnated with additional ceramic refractory material.

Investment castings used in different applications have various requirements for the size of allowable inclusions. Therefore, the pore size of the filter used to filter molten metal will depend on the intended application of the product casting. The shape and size of the holes can be selected to allow the molten metal to flow efficiently while retaining all substances exceeding a predetermined size on the filter.

Various hole shapes can also be used, including round, polyhedral and irregular shapes. Working examples of filters have pore sizes in the range of about 0.005 inches (0.13 mm) to about 0.05 inches (1.3 mm). The porosity is from about 10 pores per inch to about 30 pores per inch.

Ceramic foam filters are basically divided into 6 pore sizes: 10PPI, 20PPI, 30PPI, 40PPI, 50PPI, and 60PPI. The larger the number, the smaller the aperture. But in actual practice, the four types of 10PPI 20PPI 30PP 40PPI can meet the needs of customers.

Aperture selection

1. The casting: 10~30ppi

2. Semi-continuous casting: 30~60ppi

3. High-quality aluminum or sheet: 50~60ppi

4. Continuous casting and rolling: 50~60ppi