Deslagging Flux has the ability to absorb inclusions to float to the surface of the molten aluminum and form dry slag. The compound in the flux reacts with the impurities in the aluminum liquid, so that the oxide becomes more stable, and it is easy to generate high-temperature oxides with a smaller affinity for molten aluminum, thereby improving the slag removal power. Inclusions and hydrogen are adsorbed by the bubbles generated in the reaction and outgas as the bubbles rise and overflow the molten aluminum surface. At the same time, some inclusions are also removed as the bubbles rise to the surface.

Deslagging Flux Manufacturing Process

Weigh various ingredients by weight.

Pour the weighed ingredients into the mixer and stir to make them evenly mixed.

Pack the well-mixed mixture with utensils and put it in a drying box for drying.

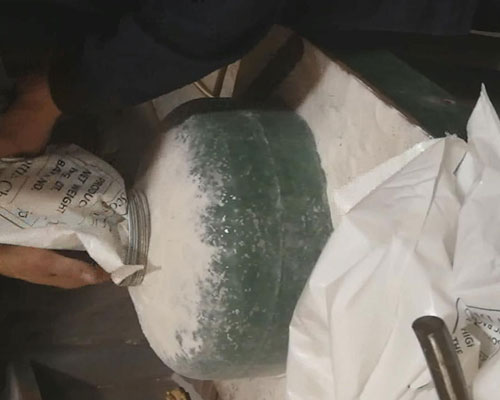

After drying to form lumps, crush it into powder form, and pack it into a bag according to the weight and seal it.

Aluminum alloy slag remover agent is suitable for the slag removal of all types of aluminum alloys except for high magnesium content of aluminum-magnesium alloys and hypereutectic aluminum-silicon alloys, and can also be widely used for cleaning furnace walls and furnace bottoms during furnace cleaning. The slag can be manually thrown and stirred during use, or inert gas injection can be used.

When the manual throwing and stirring method is adopted, the slag remover is manually and evenly thrown onto the surface of the aluminum liquid, and stirred, the street scum is generated and is obviously separated from the aluminum liquid, and the scum is removed with a slagging tool.

When the inert gas blowing method is used, the slag remover is uniformly sprayed into the melt with a special blowing device, and the spraying is performed while stirring, and the blowing gas is Ar or N2. This spray method not only strengthens the slag removal effect, but also enhances the degassing effect, and at the same time greatly reduces the operating strength of the workers, so it is suitable for melt processing in furnaces, ladles, crucibles and transfer transition vessels.

The deslagging flux provided by AdTech has good spreadability, separation and refining properties, and has the characteristics of wide application range and convenient use. Compared with existing fluxes, in addition to outstanding slag removal effects, it also has H2 and coverage.

For example, on a casting and rolling production line, the slag remover and flux provided by the present invention are respectively added according to 0.3% of the processed aluminum melt volume, and the cast-rolled slab sample is cut for oxidation slag inclusion measurement. The measurement results show that under the same conditions, the average number of oxidized slag inclusions in the sample treated with the slag remover provided by the present invention is 21.1, which is 42.3 less than the 63.5 treated with flux.

Under the same conditions, the H2 removal effect of the present invention is 40% higher than that of flux, and when the slag remover provided by the present invention is sprayed with N2, its N2 removal effect is 50.6% higher than that of flux, and the N2 removal rate reaches 81.5%. When the slag removing agent is used to purify the aluminum alloy melt, in addition to the characteristics of thorough slag removal and clean separation, the metal content in the formed slag is greatly reduced to less than 2%.