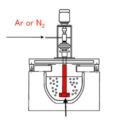

In the molten aluminum degassing process, degassing equipment uses inert gas with a purity of 99.99% to remove hydrogen and slag from molten aluminum. The rotating silicon nitride rotor breaks the ammonia (or argon) blown into the aluminum water into a large number of dispersed bubbles and disperses them in the molten metal.

Bubbles in the solution rely on the gas partial pressure difference and the principle of surface adsorption to absorb hydrogen in the solution, adsorb oxidized slag, and be taken out of the solution surface as the bubbles rise, so that the solution can be purified.

Because the bubbles are small and dispersed, they are evenly mixed with the molten aluminum, and then rotate and slowly float up in a spiral shape, and will not form a continuous straight-up air flow when in contact with the solution. Both hydrogen and nitrogen can be used as inert gases to degas the aluminum liquid.

Degassing Process

When the inert gas is introduced into the melt, the hydrogen present in the melt diffuses into the rising bubbles, and the slag particles adhere to the surface of the bubbles, which causes the slag particles to be washed to the highest surface. In addition, the element to be removed may react with one or more reactive components of the gas introduced into the melt.

Hydrogen is removed from the melt by diffusing into the rising bubbles. This is caused by the partial pressure difference between the melt and the gas, and the diffusion rate is determined by the partial pressure difference between the gas and the melt and the contact surface area between the gas and the melt. The contact time between the gas and the melt is also an important consideration.

The gas bubbling through the melt must have the lowest possible hydrogen or moisture content. If it is assumed that the partial pressure of hydrogen in the gas is approximately zero, the difference in the partial pressure of hydrogen at the beginning of the flush will be large. The huge pressure difference forces hydrogen from the melt into the bubbles. This means that hydrogen easily diffuses into the bubbles, and a large amount of hydrogen is removed.

AdTech degassing unit is a rotating rotor degassing device equipped with an imported hydraulic lift to measure the temperature of molten aluminum online.