The purification effect of aluminum alloy melt refining in the furnace is limited, and the melt is prone to secondary pollution during the flow process. So it is difficult to control impurities (hydrogen, alkaline metals, non-metallic inclusions) in the melt. Especially in the high-temperature and rainy season from June to September, the pores and inclusions in the ingot seriously affect its internal quality, resulting in a decrease in the yield of aluminum. Therefore, the degassing equipment for aluminum has been the key research and improvement object of AdTech company. In recent years, several casting lines have been technically modified.

Degassing Equipment for Aluminum

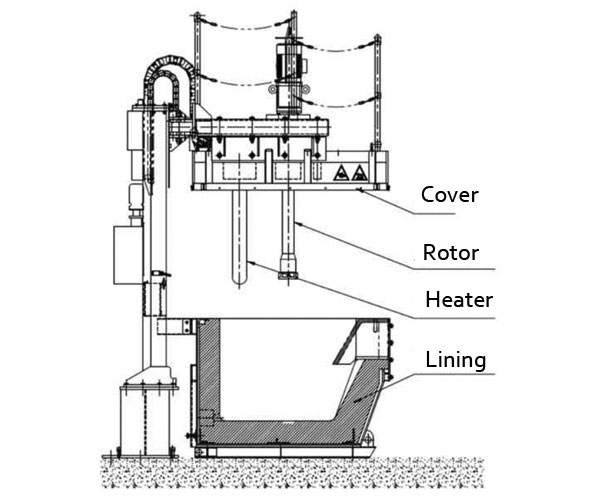

The degassing box includes two interior chambers of the purification chamber and the heating and insulation chamber. It is separated by a SiC material partition, the bottom of the two chambers are connected. The aluminum alloy liquid flows into the insulation from below the partition after degassing and slag removal in the purification chamber. The insulation room adopts U-shaped silicon-carbon support jacket silicon carbide protective tube to heat it. The outer shell of the box is made of 10 mm steel plate, and the inner lining is made of refractory material. The upper part of the sidewall equips with an observation and inspection slag port, and the bottom has a slag port.

The front and back of the processing box is an independent lumen. It is convenient for the heater to conduct directly and carry out the submerged flow of the processed aluminum alloy liquid. A slag removal door is provided at the lower part of both sidewalls of the box body, and the slag removal can be completed without starting the box cover, which extends the service life of the inner chamber of the box body. And its thermal insulation performance is also improved. The degassing unit has good sealing, which can prevent air from entering the box and avoid secondary pollution of the aluminum alloy liquid.

Degassing Process and Principle

Refined gas process: inert gas storage tank → online degassing device gas control cabinet → graphite rotor nozzle → processed aluminum alloy melt → purification and degassing treatment.

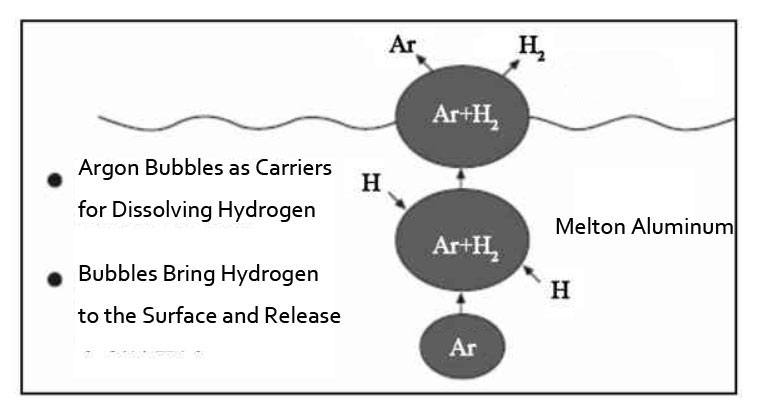

Working principle: A degassing device is placed between the holding furnace and the casting machine. In the degassing treatment tank, the nitrogen blown into the aluminum alloy melt is shredded by the rotating graphite rotor, forming a large number of dispersed bubbles. So the aluminum alloy liquid and Nitrogen gas is fully contacted in the treatment tank. According to the principle of air pressure difference and surface adsorption, bubbles absorb hydrogen in the melt and adsorb oxidized slag. It rises to the surface of the melt to form scum. The aluminum alloy melt flows from the outlet of the degassing device to the casting machine. The aluminum alloy liquid continuously enters the degassing device, and nitrogen is continuously blown in. With the purification process, the purpose of purifying the aluminum alloy liquid is achieved.