Aluminum is a metal used often for its relative strength given its lightweight. When aluminum is cast, however, impurities known as inclusions can create weak points in the product. These inclusions will lead to defects in the structure of the aluminum alloy casting. With the demand for higher quality aluminum products increasing, especially in the aerospace industry, so does the need for the quality of aluminum alloy products. In order to remove impurities from the melt to provide cleaner, better quality aluminum, one of the most effective cleaning methods is Degassing Aluminum. It is therefore essential to remove hydrogen and non-metallic inclusions from the molten metal prior.

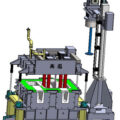

Degassing Unit for Aluminum Alloy

Molten aluminum is extremely reactive, so when it comes in contact with moist air or wet tools, the water decomposes to release hydrogen in the melt. And the dissolved gas has an overriding effect on the distribution and amount of porosity and shrinkage. Degassing Aluminum is a process used to remove hydrogen and other solid impurities from the molten aluminum. Degassing aluminum can prevent and minimize the introduction of hydrogen in the melt, and remove the hydrogen prior to pouring.

AdTech has long been aware of the need for an effective fluxing gas treatment to remove hydrogen and inclusions. So the online degassing unit by AdTech can meet this requirement and achieve the best possible degassing efficiency. The rotary degassing has a major breakthrough in automated, efficient, cost-effective degassing. The principle of degassing machines needs a rotor, it can generate very fine bubbles of inert gases that are evenly and consistently distributed throughout the metal bath.

Degassing Unit has an ultra-long life furnace body using new high-silicon molten material manufacturing technology. The degassing rotor, heater protection sleeve, and thermocouple protection sleeve are all made of silicon nitride (Si3N4) ceramic manufacturing technology. It is to exclude hydrogen and other residues contained in molten aluminum and its alloys that affect its quality and mechanical properties.