At present, the most widely used ceramic plate filter device, but its independent application in high-end products has greater limitations. Generally, ceramic plate filter devices need to be matched with other filter devices, such as deep bed or tubular filter devices. Tubular and deep-bed filtration devices are widely used in high-end aluminum processing products, and they occupy most of the industrialized high-end aluminum melt purification market.

Although the deep bed filter and the foam ceramic filter have different structures, the interception and capture mechanism of impurity particles is basically the same.

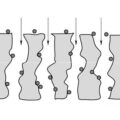

Tubular filters can filter out impurities, mainly in the following four situations:

- Direct interception. When the size of the impurity particles is larger than the pore size of the filter medium, they are blocked out of the pores and filtered out.

- The inertial force causes the impurity particles to deviate from the flow direction of the fluid, and are attracted by the thin wall of the pore of the filter medium and are retained.

- The impurity particles make irregular Brownian motion in the melt. When it collides with the filter medium, it is adsorbed by the medium and stays.

- The impurity particles are deposited due to gravity and captured on the wall of the filter medium.

The advantages of the deep-bed filter devices are thick filter layer, long flow path, and many impurity particles adsorbed. The flow rate is large, up to 5-100t/h, which is suitable for large-scale and mass production.

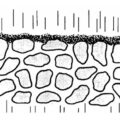

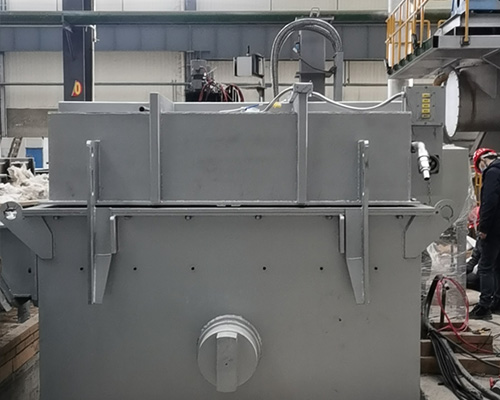

The deep bed filter consists of several layers of alumina balls (about 15mm in diameter) and a layer of gravel 6.68-3.327mm. The particle size selection of the filter material and the distribution of different layers play a major role in optimizing the filtration efficiency and extending the service life of the filter. The inlet has a filter bed supported by a grid, and the capacity of the closed container can be controlled within the range of 5-100t/h according to needs, and the design flow rate is 5-100t/h.

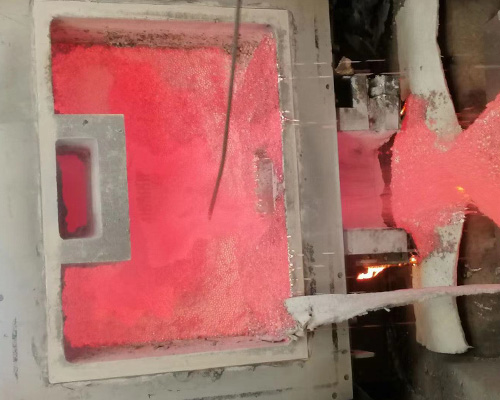

Before the liquid metal is filled, the filter bed must reach a temperature thoroughly to ensure that there is no solidification in the filter bed. Dry air or another inert gas is circulated to guide the filter to preheat. The gas is sent into the lid, and the air is heated to a high temperature by the resistance wire radiating in the lid, and then sent down to the filter bed and through the pipe to the outlet. The preheating temperature is monitored by a thermocouple.

When the filter bed reaches the temperature suitable for charging, the initial filling operation is to send the aluminum liquid into the plane layer of the filter bed through the inlet pipe, and obtain the required laminar flow under the proper aluminum liquid flow rate. It is evenly distributed at the bottom of the filter bed, and then slowly passes through the filter bed to the surface.