Since the organic foam impregnation method successfully developed CFF filters for aluminum melt filtration in 1978, it has been rapidly promoted in the aluminum industry because of its low cost, high filtration efficiency and adaptability. Developed countries have developed early research and development of CFF filters for aluminum, with many innovations and many evaluation methods. In-depth research has been carried out on the filtration mechanism, material, preparation process and utility evaluation of CFF, and many results have been achieved.

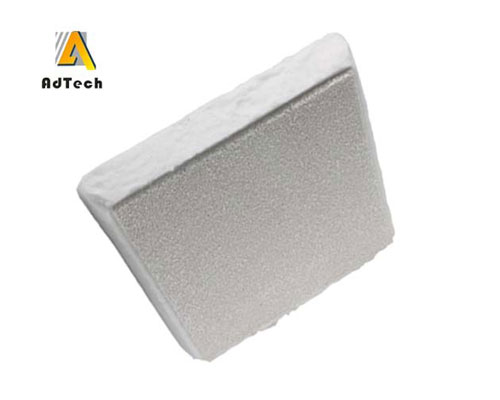

CFF Filters

(1) The pore size of the ceramic foam filter continues to decrease, from the conventional 20-40ppi (the number of uneven holes per inch) to 50-80ppi, and the filtration rate of inclusions below 20m has reached more than 90%;

(2) The use of surface activation coating, matrix toughening and other technologies to greatly improve the thermal strength, melt erosion resistance and filtration efficiency of the product. The filter can be used continuously for 2 to 4 times, and the single plate can filter aluminum up to once.

(3) Use technologies such as multi-stage filtration, pore gradient multi-layer composite CFF and the combination of CFF and other filtration methods to improve filtration efficiency. For example, AdTech’s composite filter plate has a combination of 30/50ppi,30/60ppi,30/70pi, and other combinations, which is about 15% higher than ordinary single-stage filtration efficiency.

The purpose of CFF filters filtration utility evaluation is to comprehensively judge and analyze the filtration system used. The purpose is to comprehensively compare the filtration capacity, establish evaluation criteria, make the selection of filters more scientific, and seek to optimize the product performance by the most economical and reasonable filtering method. The evaluation contents include the mechanical properties at room temperature, physical and chemical properties at high temperature, service life, impurity removal effect, rapid and accurate judgment of filtration efficiency, service cost, etc. the most critical evaluation index of filtration effectiveness is filtration efficiency, that is, the removal rate of specific inclusion content before and after melt filtration.