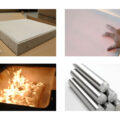

CFF Aluminum Melt Filtration can effectively remove various inclusions in the cast aluminum melt of aluminum rods, aluminum ingots, aluminum plates, and improve the cleanliness of aluminum liquid, thereby improving the quality and productivity of aluminum rods, aluminum ingots, and aluminum plates, reducing costs.

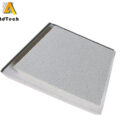

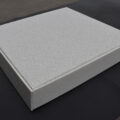

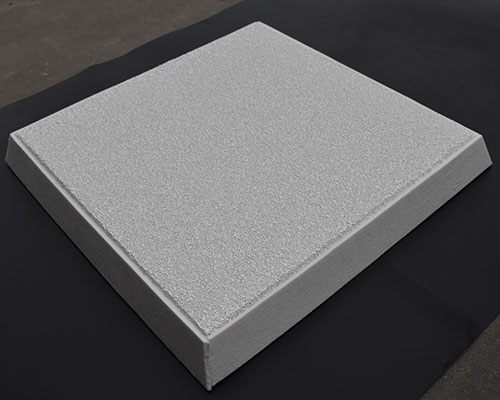

CFF (Ceramic Foam Filter) aluminum melt filtration can not only remove physical inclusions through surface interception and adsorption, but also has the effect of solvent purification. Ceramic foam filter (CFF) is currently the most widely used filter for aluminum melt filtration. Its advantages are high porosity, high filtration efficiency, convenient replacement, low cost, strong adaptability, and can filter solid inclusions and separate some liquid inclusions.

Foam ceramic filter is a kind of porous ceramic product with porosity as high as 70% to 90%, with a three-dimensional network framework and interpenetrating pore structure. It is widely used for the filtration of molten metal in non-ferrous alloys, cast iron, and cast steel. The foam ceramic filter production process is as follows: foam plastic is used as the skeleton, coated with a ceramic slurry, and fired at high temperatures.

Because ceramic foam has a three-dimensional network structure, its filtering mechanism is:

By selecting foam ceramics with suitable pore size, there are a large number of oxide inclusions, slag and other large impurities in the molten metal using mechanical methods to screen and filter.

With the increase in the number of captured inclusions, a “filter cake” composed of large inclusions is formed on the surface of the inlet of the filter screen to enhance the filtering effect.

The ceramic foam filter has a large surface area inside, which is conducive to adsorbing a large number of fine impurities. At the same time, after the liquid metal passes through the ceramic foam, the liquid metal changes from turbulent flow to laminar flow, which changes the flow state and makes the filling more stable.

Therefore, it can effectively improve slag inclusion defects, reduce the content of gases and harmful elements in the molten metal, improve the structure, improve the mechanical properties, and improve the overall yield and surface quality of the castings.