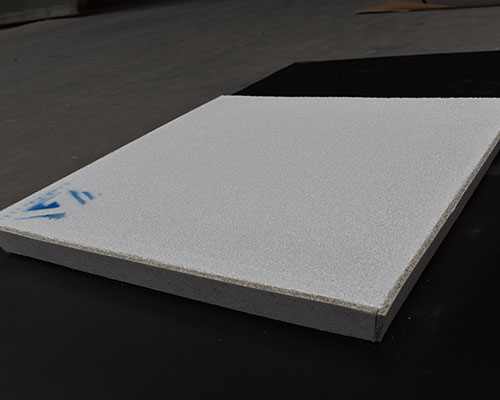

The degassing and CFF filtering method is important for aluminum casting. It is a method of processing molten aluminum and aluminum alloys to remove solid and gaseous impurities therefrom. The molten metal flows through a series of successively arranged degassing and filtering stages. The ceramic foam refractory filter media filters molten metal to remove finer particles. In addition to reducing the thickness of the surface oxide layer formed during casting, the CFF filtering method also provides improved surface quality of cast products and reduces subsequent remedial re-work or scalping.

It is well known in the aluminum casting art that surface imperfections, such as pits, vertical folds and oxide formations, that form during ingot casting can develop into cracks during casting or subsequent processing steps. Material that exhibits cracks often requires expensive remedial rework to salvage the material, or outright scrapping of the material if the cracking is extensive.

Most cast aluminum alloys are worked subsequent to casting, by various operations well known in the casting art to include: hot rolling, cold rolling, extruding, forging, drawing, ironing, aging, forming and stretching. The cracked ingot must be re-melted and re-cast, as defective ingots cannot be processed further and have little commercial value. Surface imperfections in aluminum cast ingots remain a significant problem in alloy art.

A method of continuously treating molten aluminum and aluminum alloys to remove impurities and gases therefrom comprising the steps of:

Deslagging by filtering the molten aluminum to remove relatively large size solid impurities therefrom;

Fluxing the molten aluminum to remove hydrogen gas therefrom;

Adsorbing selected impurities by passing the molten aluminum over an adsorptive refractory material having an adsorptive affinity for said selected impurities in the molten aluminum;

Filtering the molten aluminum through porous ceramic foam refractory filter medium to remove impurities not removed in said deslagging and adsorbing steps.