Ceramic foam filtration for casting is considered a major breakthrough in the aluminum industry and is widely used in semi-continuous casting and continuous casting. The filtering function of ceramic foam filters has been widely used in most aluminum foundries.

In the smelting process of aluminum alloy, non-metallic inclusions are produced due to the unclean material and the influence of the external environment. At the same time, during the casting process, due to the metal turbulence, dripping and splashing caused by the contact of large liquid metal with air, the oxide film formed by the liquid also participates in the aluminum liquid. The inclusions in the molten aluminum break the continuity of the metal. Therefore, it reduces the processing performance and maintainability of aluminum alloy, and affects the casting quality.

The Ceramic foam filter-PZr is made of high-temperature sintered ZrO2 molten material. It can be used under high temperature, high strength, corrosion resistance, and minimum volume change. It can effectively filter out micron-level inclusions in molten aluminum. Mainly used for aviation, transportation and other aluminum alloy precision casting.

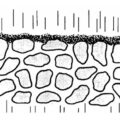

The ceramic foam filter immersed in the aluminum melt is tightly plugged with silicic acid cotton. Liquid aluminum can only pass through the serrated holes of the ceramic foam filter. Due to the combined effect of axial pressure, friction, surface adsorption, and chemical forces of liquid flow. The inclusions carried in the aluminum water are firmly retained in the pores of the ceramic foam filter. The surfaces and gaps in the cave are separated from the liquid phase of the metal.

The ceramic foam filtration effect for casting depends on the pore size and thickness of the ceramic foam filter, and the speed at which the aluminum melt passes through the filter. The thicker the ceramic foam filter, the smaller the pore size, the longer the aluminum liquid flows through the ceramic foam filter, and the greater the chance of collision. In addition, the inclusions are retained, and the chance of depositing and adsorbing on the pore wall is greater.

It should be noted that when the speed of the filtrate flowing through the ceramic foam filter is too low, it is not easily absorbed and cannot flow smoothly through the filter pores. When the rate of change is too high, the liquid metal flow will wash away the solid inclusions from the hole wall and may remove them. The optimal flow rate is determined by production practice.